Non-harmful rubber based materials in food and drink production environments has numerous benefits for the health and safety of both consumers and workers. These materials are designed to minimise any potential risks associated with contamination and ensure the integrity of the products being produced. Here are some key advantages:

1. Consumer safety

The use of non-harmful materials prevents the risk of chemical or physical hazards from leaching into the food or drink products. This ensures that consumers are protected from potential health issues, such as food poisoning or allergic reactions.

2. Compliance with regulations

Many countries have strict regulations regarding the materials that can come into contact with food and beverages. By using non-harmful materials, producers can ensure compliance with these regulations, avoiding legal issues and potential product recalls.

3. Improved product quality

Non-harmful materials, such as food-grade plastics or stainless steel, are designed to be resistant to corrosion, contamination, and degradation. This helps to maintain the quality and freshness of the food and drink products, preventing spoilage and extending their shelf life.

4. Ease of cleaning

Non-harmful materials are often easier to clean and sanitise compared to traditional materials. They are resistant to staining, odours, and bacterial growth, reducing the risk of cross-contamination. This promotes good hygiene practices and reduces the chance of food borne illnesses.

5. Environmental sustainability

Many non-harmful materials are also environmentally friendly. For example, using biodegradable or compostable materials reduces the impact on landfills and contributes to a more sustainable production process.

6. Worker safety

Non-harmful materials play a key role in ensuring the safety and well-being of workers in food and drink production environments. For instance, they can reduce exposure to harmful chemicals and prevent accidents such as cuts or burns. By prioritising worker safety, companies can maintain a healthier and happier workforce.

7. Brand reputation

Using non-harmful materials demonstrates a commitment to consumer safety and responsible production practices. This can enhance a company’s brand reputation, increasing consumer trust and loyalty. It also positions the company as a leader in sustainability and responsible manufacturing.

Some example applications are:

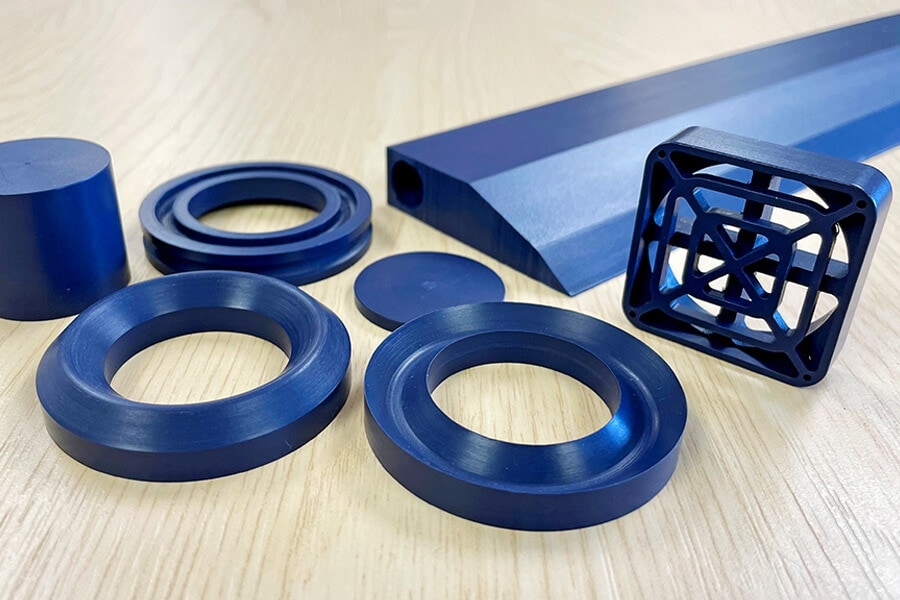

Gaskets and Seals

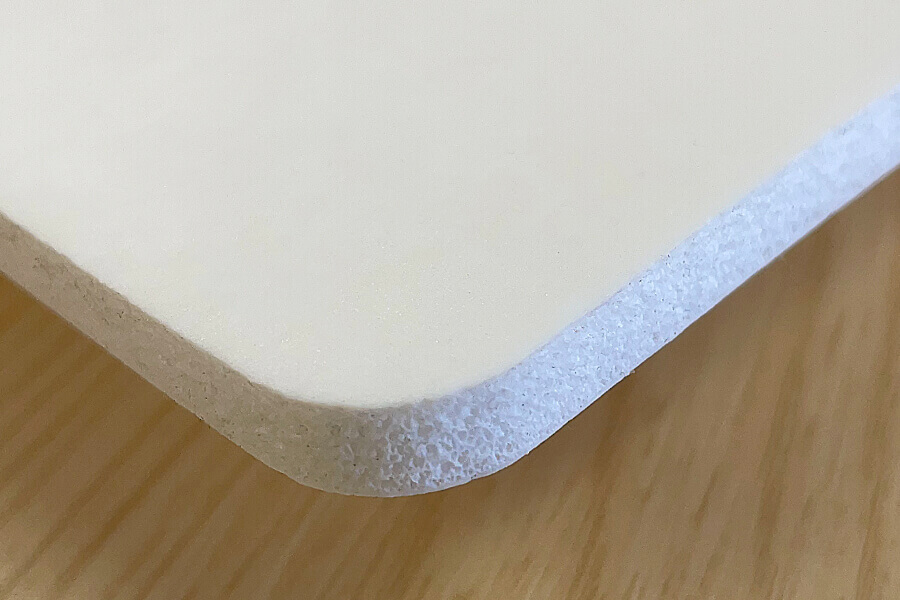

Silicone rubber sheetings are used to create gaskets and seals for equipment and containers in both food & drink and pharmaceutical sectors. These materials provide excellent sealing properties, preventing leakage and contamination.

Conveyor Belts

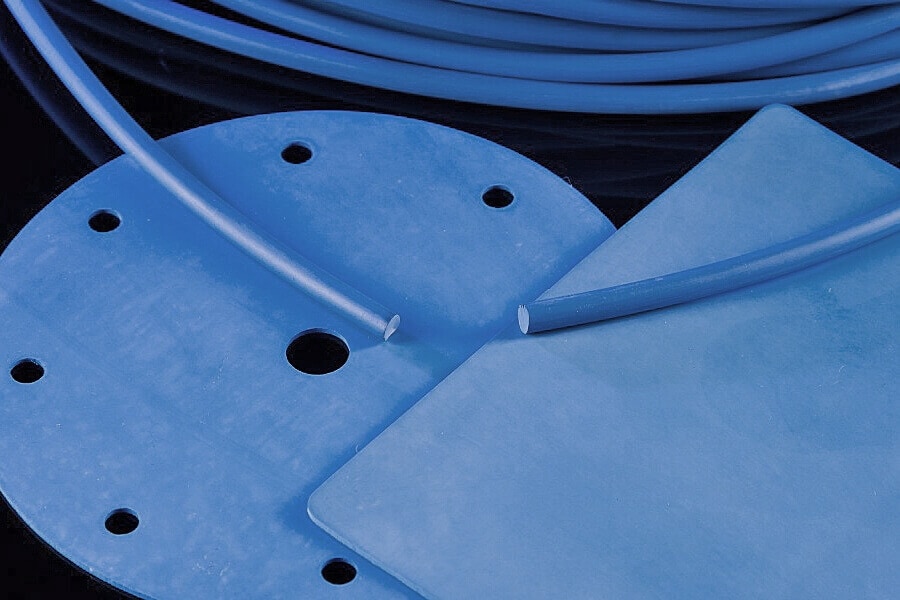

Silicone rubber sheetings can be used as a conveyor belt material in food processing industries. They offer resistance to high temperatures, oils, and chemicals, making them suitable for conveying hot or sticky food products.

Baking Mats and Pan Liners

Silicone rubber sheetings are commonly used as non-stick baking mats and pan liners due to their heat resistance, easy release properties, and ease of cleaning. They help in preventing food from sticking to the baking surface, making baking processes more efficient.

Tubing and Hoses

Silicone rubber sheetings are utilised in the food & drink and pharmaceutical industries to manufacture tubing and hoses for fluid transportation. These materials offer excellent flexibility, durability, and resistance to chemicals commonly found in these industries.

Medical Devices

In the pharmaceutical industry, silicone rubber sheetings are used for manufacturing various medical devices, such as seals, gaskets, and tubing. Silicone is biocompatible, meaning it does not react with living tissues and can be used in direct contact with the human body.

Encapsulation and Insulation

Silicone rubber sheetings are used for encapsulating and insulating electronic components or sensitive equipment in the food & drink and pharmaceutical sectors. They provide electrical insulation, protect against moisture and chemicals, and resist extreme temperatures.

Vibration Dampening

In pharmaceutical manufacturing processes, silicone rubber sheetings can be used to dampen vibrations in equipment to ensure stability and precision. This helps maintain accuracy in critical measurements and reduces the risk of equipment failure or damage.

In conclusion:

lmplementing non-harmful materials in food and drink production environments provides significant benefits, ranging from consumer safety and improved product quality to regulatory compliance and environmental sustainability. By investing in these materials, companies can safeguard the health of their consumers, protect their brand reputation, and create a safer and more sustainable production process.

See below for a selection of materials suitable for Food and Drink production.