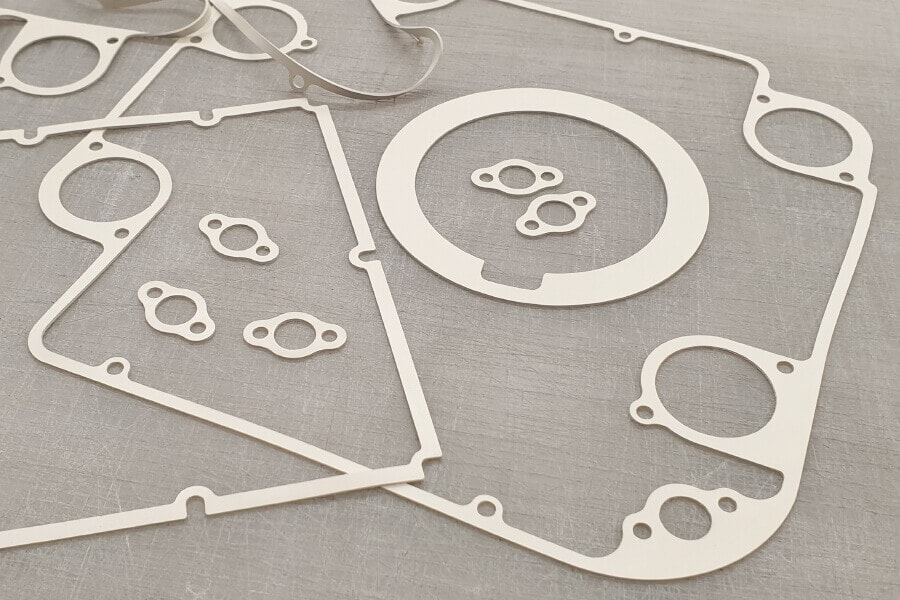

J-Flex – for custom made, precision engineered die cut or digital flatbed precision cut gaskets in premium grade elastomers.

J-Flex is the comprehensive source for all your custom cut gaskets requirements, whether you need small, medium or large volumes. Whatever your requirements, we can help with a superb range of die-cut and digital flatbed cut rubber gaskets.

Our cutting of gaskets and geometric shapes are generally in soft engineering, non-metallic materials – including:

- Natural and Synthetic Rubbers

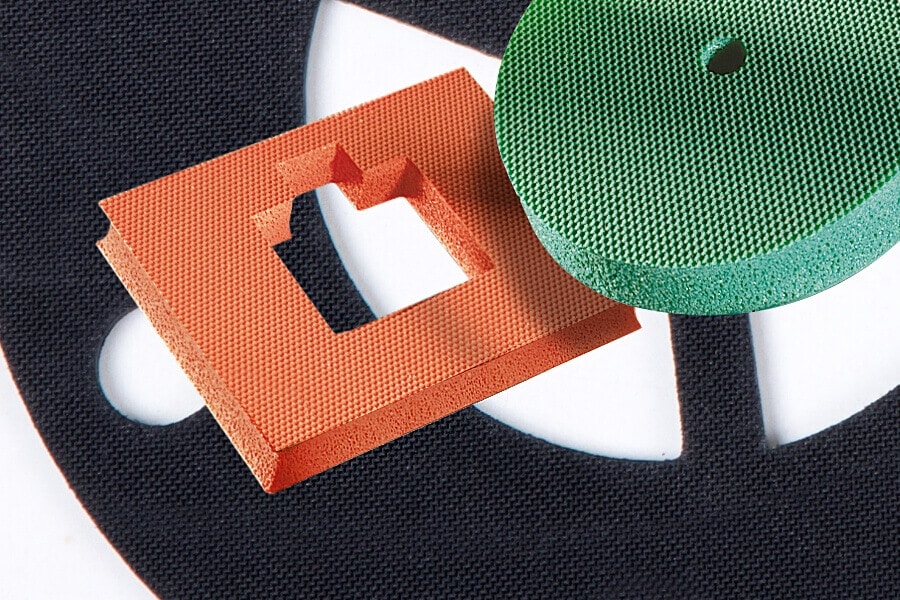

- Silicone Rubber Gaskets & Seals

- Silicone Sponge Gaskets & Seals

- Rubber Insertions and Diaphragm Materials

- Fire Retardant materials to EN45545

- Non-Asbestos Jointings

- Vulcanised Fibre

- P.T.F.E. (Polytetrafluoroethylene)

- Ceramic Papers and Jointings

- Viton™ gaskets

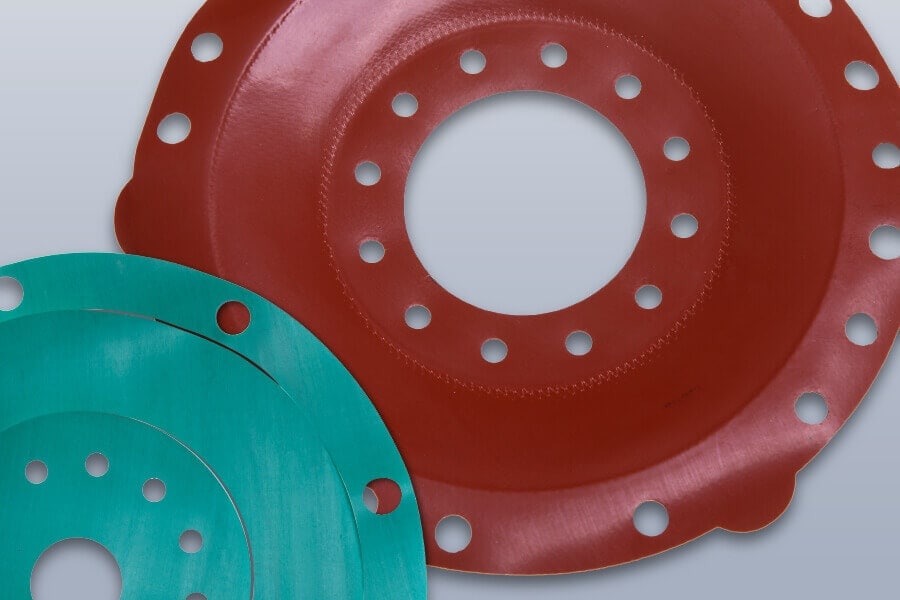

By using non-metallic materials, our die cut rubber gaskets are anti-corrosion as standard.

Whatever the size of gasket you require, we can usually help.

In addition we supply large Vulcanised ‘O’ Rings; Boiler Joints; Packings and Corrugated Metal Gaskets. All can be made to your specific requirements quickly and efficiently.

Here to help

Please note: all fields with a * must be completed.

Precision cutting

We have a large precision cutting facility, capable of cutting a wide variety of rubber/elastomer sheeting, up to 3.2m wide, ensuring total accuracy for product sizing, cut-out portions, holes & slots.

Water-jet cutting and cutter presses are also used where appropriate.

Viton™ is a Registered Trademark of The Chemours Company.

What are precision cut gaskets, and what materials are used for gaskets?

There are many different types of gaskets, but a cut gasket is a specific type that is made by cutting it out of a sheet of material and are often used in plumbing and mechanical applications where a tight seal is required. Also in electrical applications where it is important to prevent sparking. Gaskets are frequently used in environments where there is a need for complete sealing, such as in high-pressure applications where fluids and gases are involved. Precision cut gaskets are manufactured to precise tolerances and can be used in a wide variety of applications. Precision cut gaskets can also be made from metal, but these are less common.

Most precision cut gaskets are made from non-asbestos materials, such as graphite, PTFE, or mica. The material that is used will depend on the application and the desired results.

One of the most popular materials is silicone, which is often used in food-grade applications because it is non-toxic and can withstand high temperatures. Neoprene is another popular choice for gaskets, as it is resistant to oil and chemicals. Rubber is also commonly used, as it is both durable and flexible. J-Flex gaskets are made from premium grade elastomers as highlighted in the list above.

For applications that require a more robust seal, metal gaskets are often used. These are most commonly made from stainless steel, but they can also be made from other metals such as copper or aluminium. Metal gaskets are generally used in higher-temperature applications or in applications where chemical resistance is a concern.

Whatever the application, precision cut gaskets provide an excellent seal and help to extend the lifespan of equipment.

How many types of gaskets are there?

This is a common question with a variety of answers depending on the specific industry or application. In general, there are three different types of gaskets: sheet gaskets, O-rings, and spiral wound.

- Sheet gaskets – typically made from compressed non-asbestos materials, such as paper, rubber, cork, and fiberglass.

- O-ring gaskets – commonly referred to as O-rings and usually made from elastomeric materials, such as nitrile, silicone, or EPDM.

- Spiral wound gaskets – made from a strip of metal wound around a central core. The strip of metal can be made from stainless steel, carbon steel, or nickel alloy.

There are also a variety of other gasket materials, such as PTFE and graphite. The type of gasket best for a particular application depends on the operating conditions, such as temperature and pressure.

What’s the difference between Gaskets and O-rings?

Gaskets and o-rings are two common types of seals used in a variety of applications. Both create a barrier between two surfaces in order to prevent leaks, however there are some key differences between gaskets and o-rings that should be considered when choosing a seal for a particular application.

Gaskets are typically made from softer materials, such as paper, cork, rubber, or silicone. This allows them to conform to irregularities in the surface, thereby creating a tight seal. Gaskets are typically installed between two flat surfaces and rely on surface tension to create the seal.

O-rings, on the other hand, are made from harder materials, such as metals, plastics, or elastomers. This gives them a more precise fit, but they may not be able to seal as well in irregular surfaces. O-rings are installed in grooves/channels, meaning they can be compressed when installed, creating a tighter seal.

When selecting a seal for an application, it is important to consider the specific needs of the application. For example, if a very tight seal is required, an o-ring may be the better choice. If the surface is irregular or there is a need for flexibility, a gasket may be the better option.

Ultimately, the best way to choose between gaskets and o-rings is to consult with experts who can assess the specific needs of the application.