EN45545 and its purpose

EN45545 is a European railway standard that was introduced in 2013 in order to harmonise the different train management systems including fire and smoke standards. It aims to protect passengers and staff against fire on board railway vehicles.

EN 45545 applies to manufacturers of rail vehicles, including high-speed trains, regional trains, trams, subways and double-decker trains.

After a transition period of several years, it has now become a mandatory requirement throughout Europe, and all materials used in the manufacture of railway vehicles must follow the EN45545 standard to achieve the highest possible level of safety in case of fire.

EN 45545 became the unique rail fire protection standard in March 2016, and replaced the following national standards:

United Kingdom BS 6853

Code of practice for fire precautions in the design and construction of passenger carrying trains.

France NF F 16-101

Railway Rolling Stock Fire Behavior Choice of Material.

Germany DIN 5510-2

Preventive Fire Protection In Railway Vehicles – Part 2: Fire Behaviour and Fire Side Effects Of Materials and Parts – Classification, Requirements and Test Methods.

Italy UNI CEI 11170-1/2/3

Railway and Tramway Vehicles – Guidelines for Fire Protection of Railway, Tramway and Guided Path Vehicles.

Poland PN K-02511

Rolling Stock – Fire Safety of Materials – Requirements.

EN45545-2

Part 2 of EN45545 defines the most stringent requirements for the fire behavior of materials and components, including floor coverings, seats and cables of railway vehicles.

EN45545-2 aims to protect passengers and staff against onboard fire incidents in railway vehicles.

Concerning the burning behaviour of rubber materials in particular applications, the EN45545-2 specifies the test methods, conditions and constraints for reaction to fire and contains specific requirements for flame spread, flammability, heat release, oxygen index, smoke density and smoke toxicity. Smoke is a deadly by-product of any fire – as evidenced by the Kings Cross Underground Station disaster in 1987.

Test reports will indicate which tests have been approved for the material in question.

Products are then classified according to a set of 26 requirements (R1-R26) based on where the materials will be used (inside or outside the train) for a particular level of hazard. Each requirement set has a corresponding series of test performance criteria, this & the operating categories determine the hazard level.

It is therefore important for the user to know the desired requirements for the application and the associated level of danger (fire hazard).

EN45545 Requirement Sets

All ‘R’ Requirement Sets are detailed in the specifications of EN45545-2. Here are some examples:

R1 – Requirements for horizontal/vertical interior surfaces, e.g. ceiling and walls, window frames or display screens.

R9 – Suspension parts

R10 – Floor coverings

R22 – Sealings & hoses – interior

R23 – Sealings & hoses – exterior

R24 – Isolation parts

EN45545 Hazard Levels

Railway vehicles are classified in accordance with the fire hazard level associated with their design and operation.

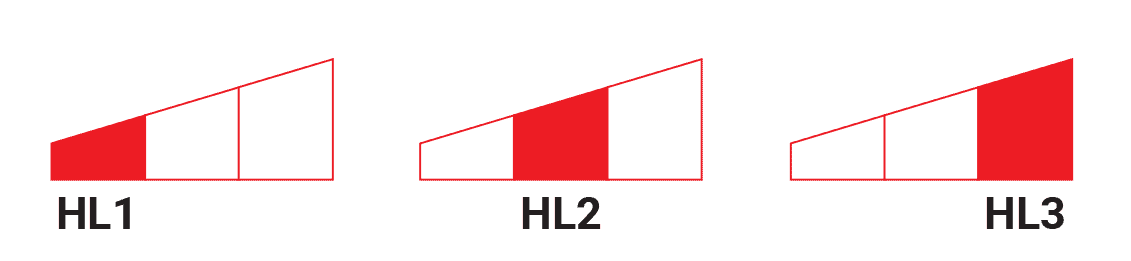

EN45545-2 defines 3 Hazard Levels: HL1 – HL2 – HL3. HL1 is the lowest level – HL3 is the highest level.

The HL classifications depend upon how many kilometres the rail vehicles are used in a tunnel, whether they are automatic (no driver), carriages with more than one storey (in Europe 2 storey trains are very common) and if sleeping compartments are on board.

The hazard level defines the operation category of the train.

| HAZARD LEVEL MATRIX | DESIGN CATEGORY | ||||

| Operation Category | (N) Standard Vehicles | (A) Automatic train with no emergency staff on board | (D) Double decker vehicles | (S) Sleeping and couchette vehicles | |

| OC-1 Above ground with good evacuation | HL1 | HL1 | HL1 | HL2 | |

| OC-2 Underground/ tunnels with good evacuation | HL2 | HL2 | HL2 | HL2 | |

| OC-3 Underground/ tunnels with limited evacuation (side evacuation available) | HL2 | HL2 | HL2 | HL3 | |

| OC-4 Underground/ tunnels with limited evacuation (no side evacuation available) | HL3 | HL3 | HL3 | HL3 |

Operation Categories

A: Vehicles forming part of an automatic train having no emergency trained staff on board.

D: Double decked vehicles.

S: Sleeping and couchette vehicles.

N: All other vehicles (standard vehicles).

Material Groups

Depending on the use & characteristics of the materials and components, EN 45545-2 specifies materials into Interiors products (IN), Exteriors products (EX), Furniture (F), Electro technical equipment (E), Mechanical equipment(M), and Non-listed products.

Testing

The standard includes a series of test methods to evaluate the fire behaviour of materials and components used in the construction of railway vehicles. These tests assess various characteristics, including ignitability, flame spread, smoke density & toxicity, and heat release rates.

Each requirement has a corresponding series of test performance criteria imposed for each fire risk level (HL 1 to HL 3).

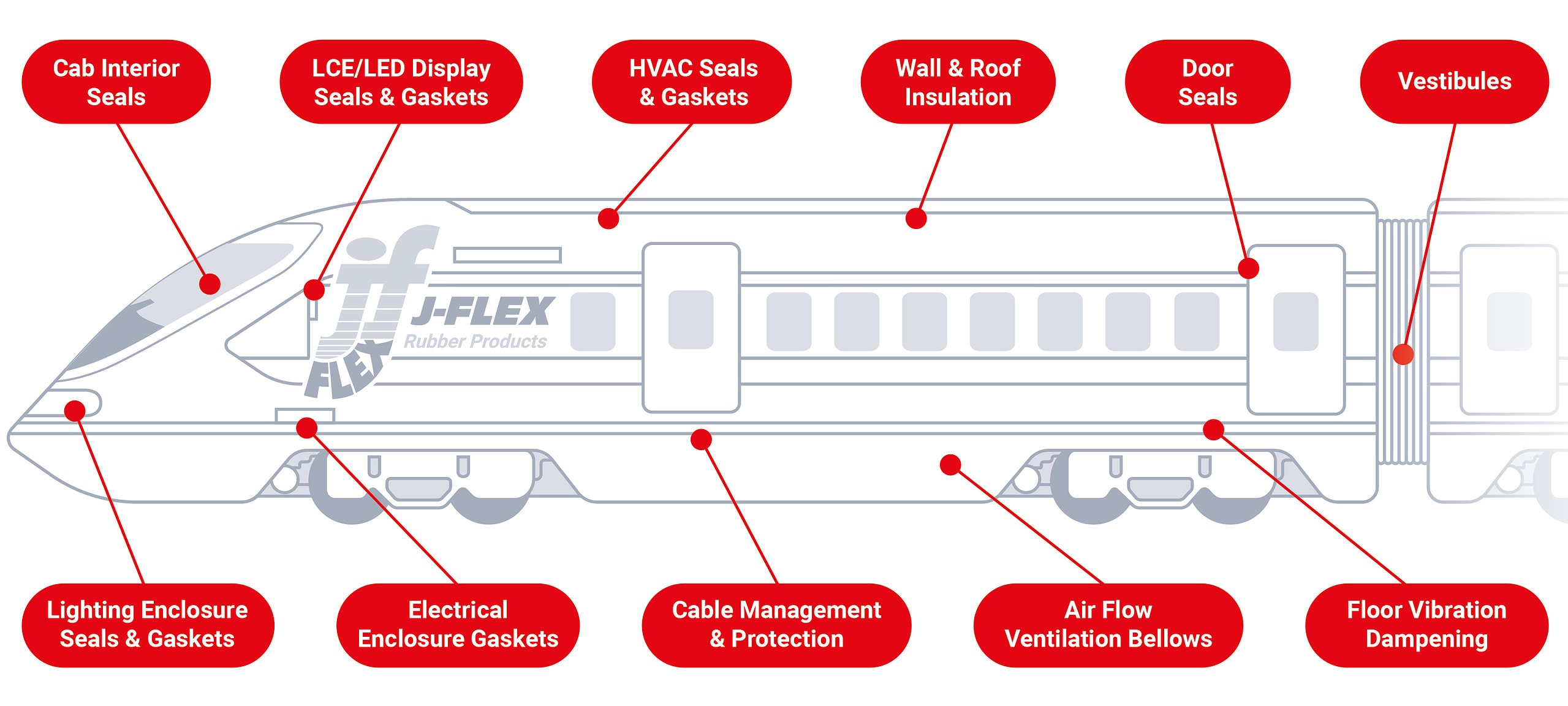

How can J-Flex help you select the correct rail product/materials?

1. The first step is to determine which product requirements apply to the product in question (R1-R26).

2. Secondly determine the fire risk (hazard level HL1, HL2 or HL3).

3. Identify a suitable EN45545 approved material that meets the above ratings and the technical requirements for the application.

It really is ideal to select a partner and products that meet all the requirements set and that have been independently tested and approved according to the EN45545-2 requirements. Working with a certified and well-experienced partner can ease selection of the right components.

Companies with material/product expertise, such as J-Flex, have a growing presence with leading players of the rail industry and offer the right product for each rail application.

Rolling Stock and Trackside Applications

Trackside applications include:

• Cable Jacketing • Signal Cable Hose • Cable Ductings

Specifications/Norms explained

EN45545-2: 2020

European Standard – Railway Applications – Fire Protection on railway vehicles.

This replaces National Standards :-

• BS6853 – British Standard

• DIN5510-2 – German Standard

• NF F 16/101 – French Standard

UL 94 V(0)

U.S. Underwriters Laboratory Standard set for testing flammability for plastics, however the standard is widely used & accepted within the rubber industry.

NFPA130

U.S. Standard specifying fire protection & life safety requirements for underground, surface & elevated fixed guideway transit and passenger rail systems.

FMVSS 302

U.S. Federal Motor Vehicle Standard relating to burning behaviour of materials used inside road vehicles such as passenger cars, trucks, buses & agricultural vehicles.

CMVSS 302

As above but issued by the Canadian motor industry.

SMP 800-C

Bombardier smoke & toxic gas generating specification.

BSS 7239

Boeing fire test for aircraft toxicity combustion.

Def-Stan 07-247 U.K.

Ministry of Defence standard & selection of materials based on their fire characteristics.

EN 13501-1

Fire Classification of construction products & building elements.

In Summary

EN45545 is a crucial European standard, which guarantees railway passenger and staff safety by setting strict fire behaviour requirements for all train materials. This mandatory rule, replacing older national regulations, ensures consistent fire protection across Europe and beyond.

In short, EN45545 ensures Fire Safety in every train journey and a safer, more secure travel experience for all.