J-Flex – for custom made, precision engineered rubber bellows in premium grade elastomers.

Whatever your requirements, industrial rubber specialist J-Flex can help with rubber bellows, rubber expansion joints, fabric expansion joints, flexibles and compensators.

J-Flex supply a wide range of flexible products, custom made to specific requirements allowing for thermal movement, isolation of vibration, and compensation for misalignment in ductwork and piping.

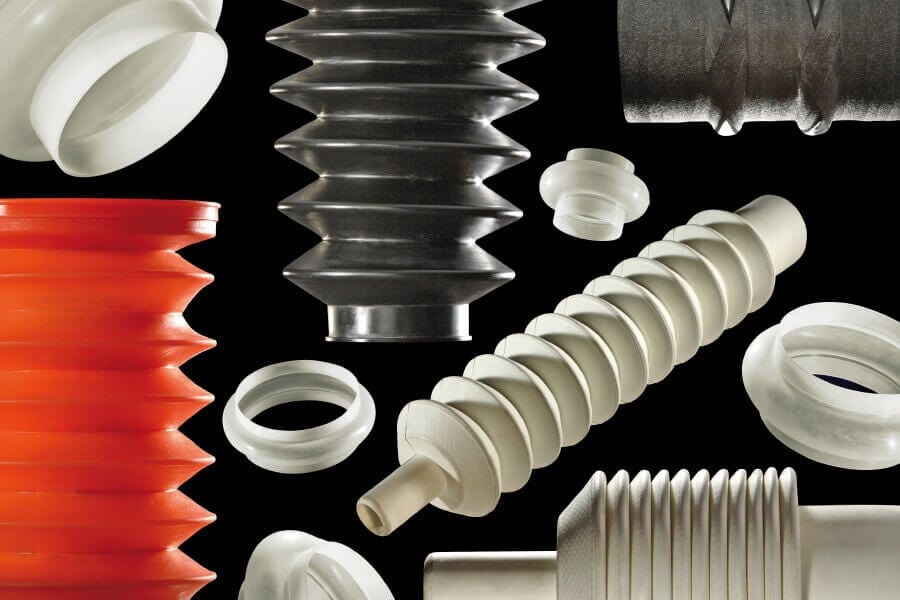

Generally, custom made to customers specific requirements, we offer:

- Bellows – Moulded or Hand Fabricated

- Standard Food Quality (FDA Compliant) Silicone Rubber Bellows

- Expansion Joints – Hand Fabricated or Sewn

- Flexibles – Fabricated from Sheet or Mandrel Built

- Socks/Cones – Fabricated from Sheet or Mandrel Built

Our joints can be supplied in any form fully assembled or open ended for site assembly. Whatever the size of rubber bellows, rubber expansion joints or fabric expansion joints you require, we can generally help.

Let J-Flex handle your flexible requirements – you’re in safe hands.

Here to help

Please note: all fields with a * must be completed.

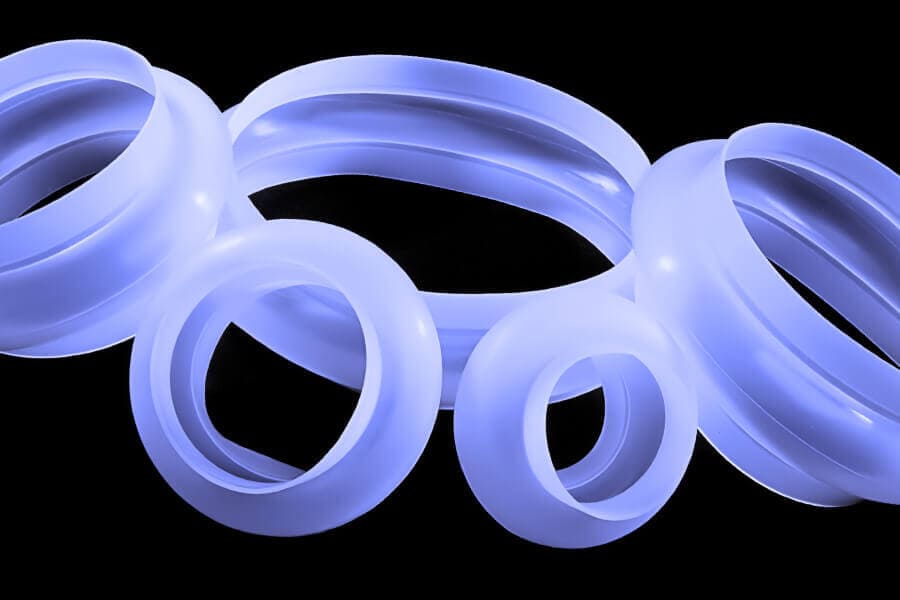

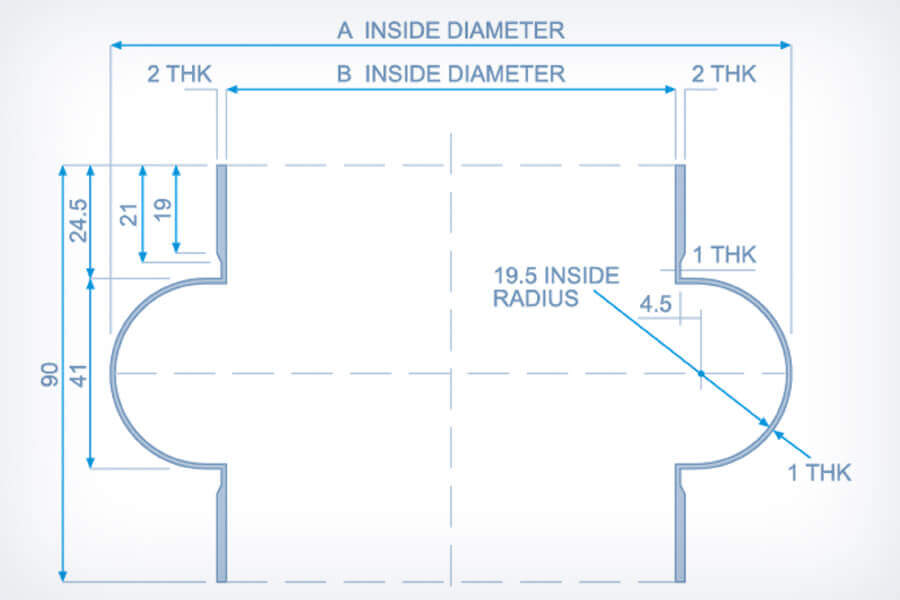

In addition we supply Vulcanised Joined Rings; Boiler Joints; Packings and Corrugated Metal Gaskets. Any of these fabricated components can be made to your specific requirements. Whatever the size of vulcanised joined ring you require, we can generally help.

What is a rubber bellow and what are rubber bellows used for?

Rubber bellows are flexible and compressible containers that are used for transit of fluids, gases or other media. They are often used as expansion joints in piping systems to compensate for movement, temperature and pressure. Rubber bellows are made from a variety of materials, including natural or synthetic rubber, and some offer reinforcement using plies of fabrics or metallics built up in layers. The number of plies incorporated can be varied according to the requirements of the working pressure and temperature. Rubber bellows are available in a wide range of sizes and shapes and can be custom designed to meet specific needs.

Rubber bellows are used in a variety of other industries, such as aerospace, automotive, pharmaceutical and industrial. Rubber bellows help to protect against vibration and noise, and they can also be used to absorb shocks. In addition, rubber bellows can be used to seal gaps and prevent leakage. As a result, they are an essential component in a wide range of applications.

What are the most commonly used materials for rubber bellows?

There are a variety of materials that can be used for rubber bellows, but some are more commonly used than others. The most common material for rubber bellows is neoprene, which is a synthetic rubber that is resistant to environmental conditions. Another popular choice is nitrile, which is also resistant to both heat and cold but has better abrasion and fuel resistance. Finally, silicone is sometimes used for rubber bellows due to its high temperature resistance.

How many types of rubber bellows are there?

There are four types of rubber bellows: square, rectangular, rectangular convoluted, and oval. They are used as expansion joints in piping systems to accommodate thermal expansion, misalignment, vibration, and movements. Rubber bellows are also used in HVAC systems and as pump connectors. The type of rubber bellows you need depends on the application and the amount of movement that is required.

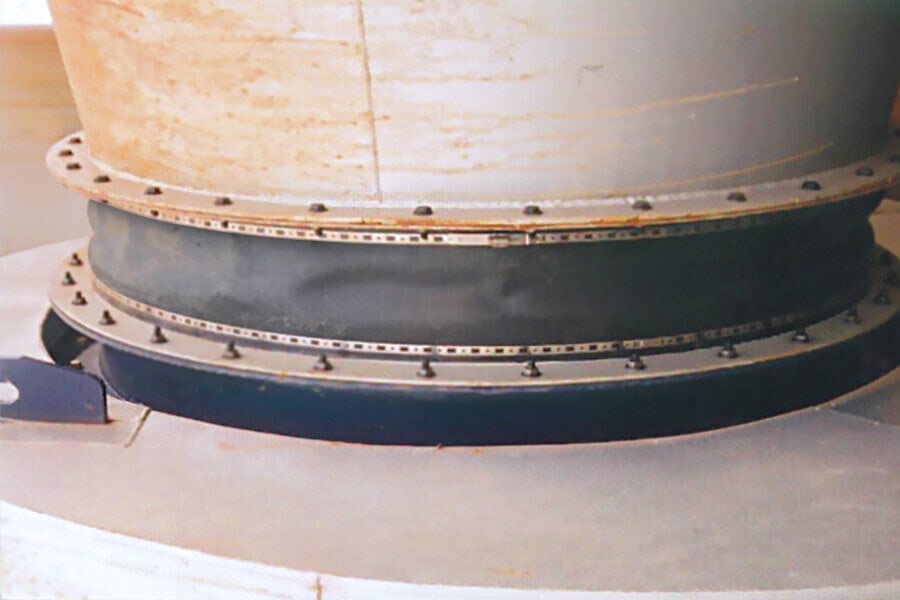

What is an expansion joint and what are expansion joints used for?

Many of the expansions joints we produce are primarily designed to allow for movements in pipe work systems due to thermal changes – temperature and pressure. This relieves stresses, protects machinery attached to the pipe work, and therefore lengthen the life of the whole system.

The ability to flex laterally and axially also allows our expansion joints to:

- Reduce noise transmission

- Isolate Vibration

- Compensate for pipe work misalignment

- Allow for mounting settlement

- Balance pressure loads

The types of movement that can be accommodated include Compression, Extension, Shear, and Misalignment.

A structural expansion joint is a device that is installed in order to absorb the thermal expansion and contraction of building materials. They are commonly used in applications such as bridges, sidewalks, and roofs. Expansion joints can be made from a variety of materials, but the most common types are rubber or pourable sealant. Expansion joints are an essential component in many different types of construction, and they play a vital role in ensuring the safety and integrity of these structures.

Are rubber bellows and expansion joints the same? What’s the difference between a rubber bellow and an expansion joint bellow?

A Rubber Bellow is a type of expansion bellow that is manufactured with a flexible elastomeric material – often used in applications where there will be movement, such as in industrial pipework.

Expansions Joints are often described as Road or Deck Joints, and are fitted on road decks, parking structures, or other building projects to provide waterproofing in ceilings and floors, but also to allow for the thermal expansion and contraction of the concrete or tarmac surfaces. They are generally EPDM, and often linked with water proofing membranes. Where a solid rubber joint is not feasible you will often see a pourable rubber being used to fill the gap between road decks. This works in the same way as the solid rubber joints, but can be used for smaller or hard to reach gaps.