High performance mouldings, rubber sheeting, extrusions, gaskets, fabrications and vacuum-forming membranes for the automotive sector.

Our automotive customer types include:

- Prestige automobiles

- Supercars

- High performance race teams

- Formula 1

- The growing EV market

- Specialist car restorers

- 4×4 manufacturers

- Motorcycle companies

providing:

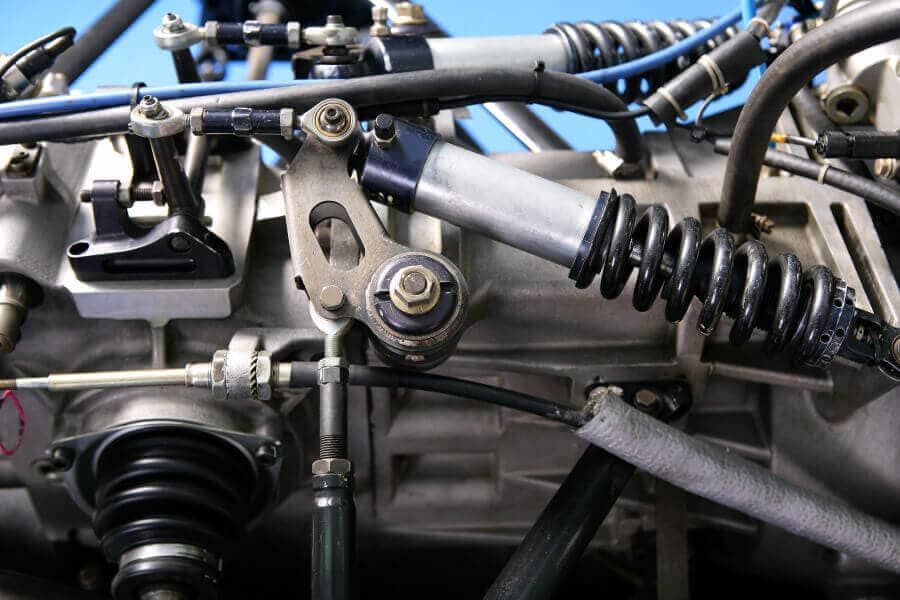

Components

– mouldings, fabrications and extrusions for any required automotive rubber parts and also the reproduction of obsolete OEM parts for the restoration of classic and unique cars.

Seals

– custom made seals, for sound and draught exclusion, as well as containment of fuel and other liquids.

Sheetings

– special sheetings such as Viton™ for linings in motorsport fuel containment bladders, custom gaskets etc.

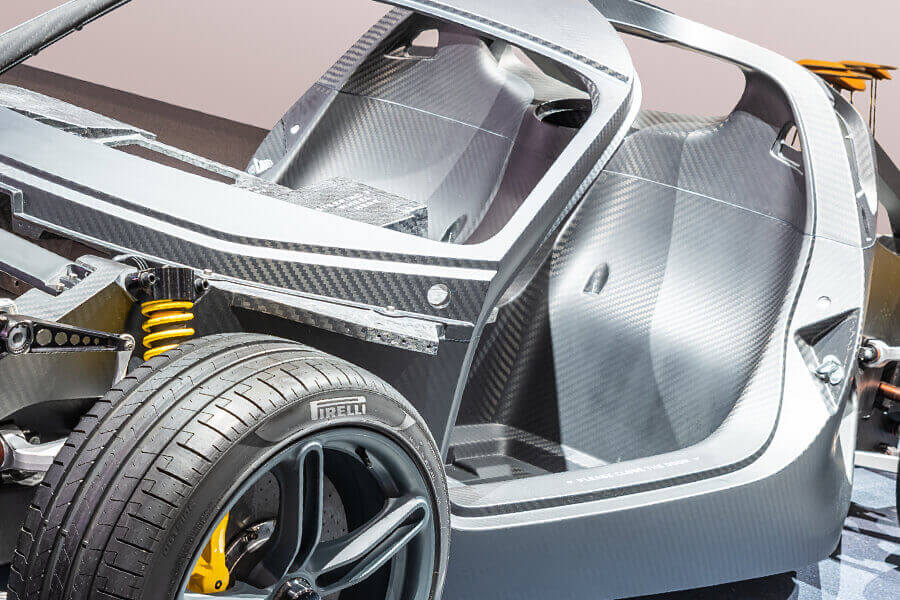

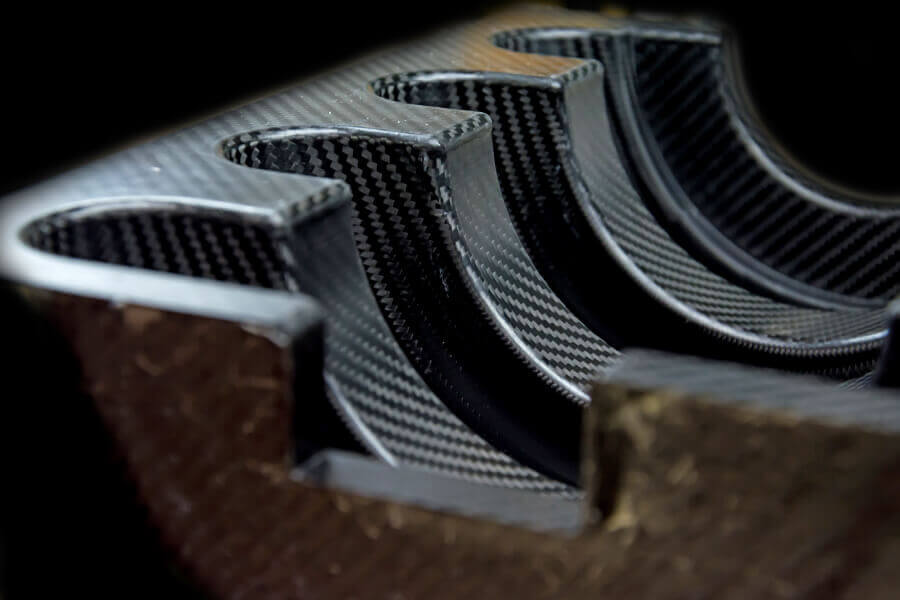

Vacuum Forming Membranes

– our Vac-Sil® quality membranes are widely used in the vacuum forming process for producing carbon chassis tubs, bespoke interior trim panels and other performance parts. Find out more.

Gaskets

– custom made gaskets to suit your requirements.

We have a large precision cutting facility, capable of cutting a wide variety of rubber/elastomer sheeting, up to 3.2m wide, ensuring total accuracy for product sizing, cut-out portions, holes & slots. See our Cutting Services for more information.

Water jet and cutter presses are also used where appropriate.

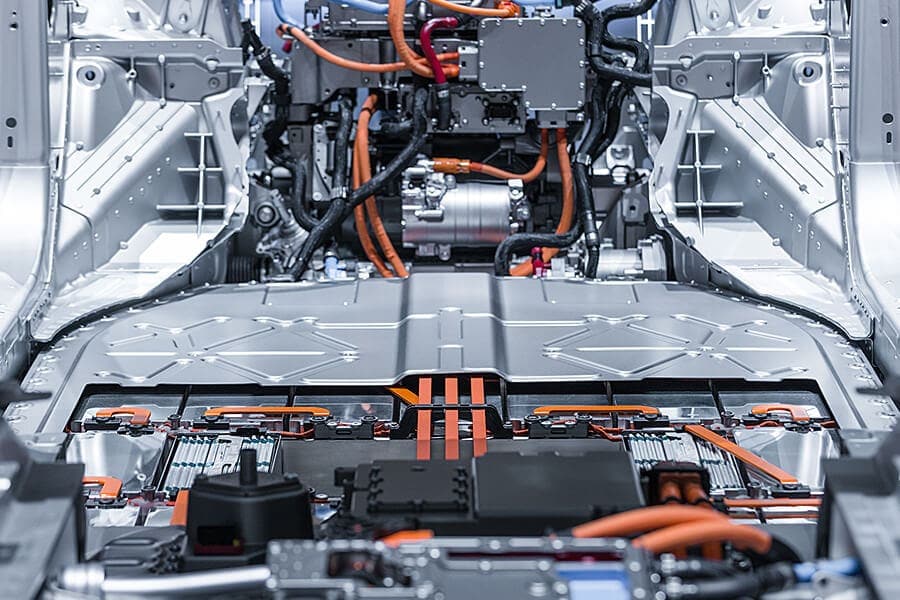

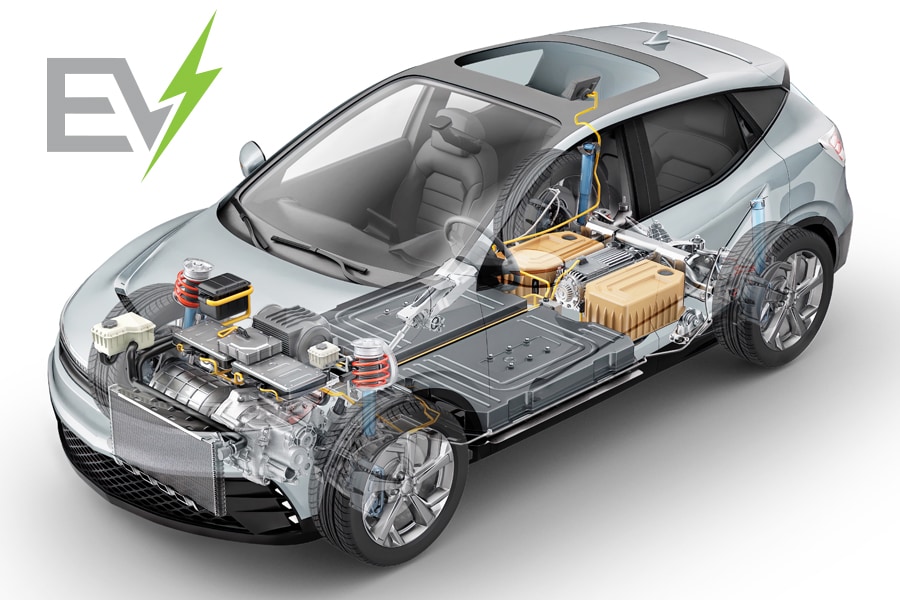

Electric Vehicles (EV’s)

We are working with, and supplying to, a number of Electric Vehicle manufacturers – providing materials and parts that are either used in the vehicles themselves or within the production/manufacturing process. Similarly with Battery Cell/Pack manufacturers.

We also have some exciting product developments we’re working on, which we look forward to bringing to market.

If you’re in the EV market, whether in be Automotive, Marine, Aerospace or otherwise, we’d love to hear from you.

The video below shows how our Vac-Sil® quality membranes are used to vacuum form various interior trim panels for a high profile prestige motor manufacturer.