Rubber is a ubiquitous material we encounter in our daily lives in various forms, from tyres to belts, gaskets, gloves, and even as an ingredient in numerous household products, but have you ever wondered how this amazingly versatile material is made? In this post, we delve into the fascinating process of Natural Rubber production.

Natural Rubber has been a phenomenal success story over the 150+ years since it was introduced to the European Industrial Revolution taking place around that time. Plantation farmers have carefully cultivated trees and have “sustainably harvested” one of the most remarkable natural elements on the planet.

Tree’s are typically tapped for around 40 years before being replaced by newer trees, carefully cultivated from saplings that have been diligently planned into plantation activity.

Harvesting Natural Rubber

Rubber production begins with the harvesting of latex, a milky sap-like substance found in the bark of certain trees, most notably the Hevea brasiliensis tree, also known as the rubber tree. These trees are typically grown in large plantations in tropical regions such as Southeast Asia, Africa, and South America, where the climate is ideal for their growth.

To obtain latex, a skilled worker, called a rubber tapper, makes a precise incision in the bark of the tree using a specialised tool. This incision allows the latex to flow out of the tree into a collection cup. The tapper repeats this process on multiple trees until enough latex is collected.

Coagulation

Once the latex is gathered, it undergoes a series of processing steps to transform it into the rubber we are familiar with. Firstly, the raw latex is sieved to remove any impurities like leaves, twigs, or insects. It is then mixed with various compounds such as acid, ammonia, and other chemicals to stabilise and preserve it during transportation.

Next, the latex is coagulated. In the past, the most common method was to add acetic acid or vinegar to the latex, causing it to curdle and form large lumps. However, nowadays, more efficient methods involving synthetic coagulants are used. These coagulants cause the latex to solidify into a thick mass resembling coagulated milk, which is then cut into smaller pieces called coagulum.

The coagulum is then washed to remove any remaining impurities. This process is repeated several times until the rubber is considered clean. The resulting material is often referred to as wet rubber since it still contains a considerable amount of water.

Sheet Formation, Smoking & Curing:

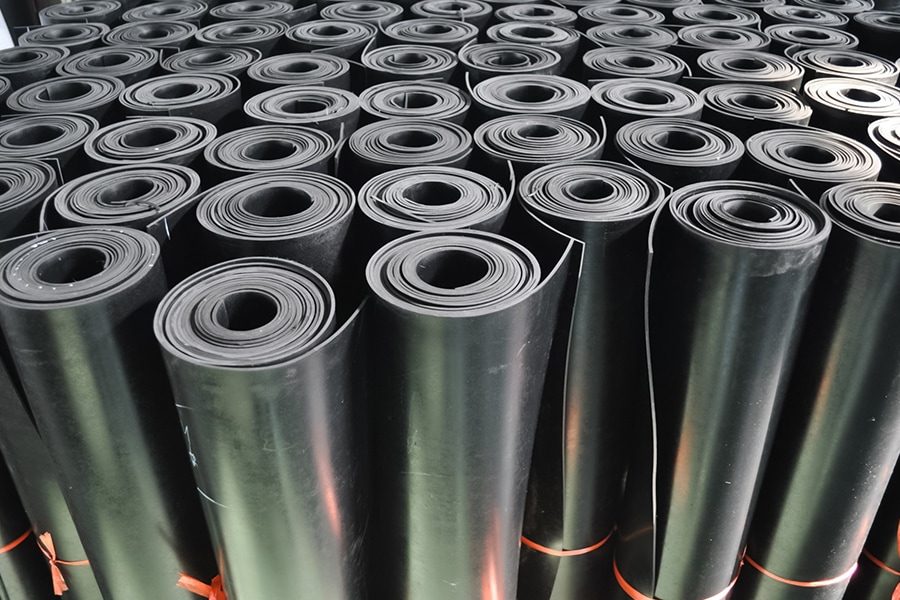

To eliminate the excess water content and improve the quality of the rubber, it is sent to a drying process. This can be achieved through various methods such as air drying, smoke drying, or mechanical dewatering. Often, the rubber is rolled into thin sheets or made into thick blocks for ease of handling and transportation. This can be done manually or through automated processes. The sheets are then hung to dry, allowing excess water to evaporate and leaving behind a rubbery material.

Once the rubber is dried, it undergoes a curing process, also known as vulcanisation. This step involves subjecting the rubber to heat and adding sulphur or other chemicals to improve its elasticity, strength, and resistance to ageing. The curing process usually occurs in large industrial presses.

Processing and Manufacturing

The cured rubber sheets are then ready for processing into various rubber products. This can involve further refining, compounding with additives to achieve specific properties, and shaping the rubber into sheets, rolls, or specific moulds to meet the desired end-use application. Manufacturers can create an array of rubber products, from tires and hoses to gloves and footwear.

Quality Control

Throughout the entire process, rigorous quality control measures are in place to ensure that the rubber meets the required standards. Manufacturers rigorously test the rubber for factors such as tensile strength, elongation/elasticity, hardness, resistance to chemical and physical stress, and resistance to environmental factors – to ensure it meets the required specifications. Only after passing these tests is the rubber considered ready for distribution and use.

A brief word on Synthetic Rubber and Silicone Rubber

While natural rubber has its merits, synthetic and silicone rubber has become increasingly prevalent.

See the links below:

Silicone Rubber: A Versatile Elastomer in Industry

What is Synthetic Rubber?

Did you know?

One particular name associated with High Grade/Abrasion Resistant Natural Rubber is Para – but do you know what Para Rubber is and where the name originated from?

Para is a region of the Amazon Forest (in Brazil), that grew a particularly high grade of Natural Rubber. The name of Para has become a generic name for products (sheetings, tubings & bellows) made in a high quality rubber. This is normally a Tan/Light Brown colour that is supposed to indicate pure latex material.

In Conclusion:

In conclusion, the journey from latex to rubber is a remarkable process that combines traditional methods with modern technology, transforming latex obtained from rubber trees into the versatile solid rubber products we utilise in our daily lives. From the rubber tapper’s skilled hand through various processing stages to the final quality checks, every step is essential in delivering a reliable and efficient material we depend on for countless applications. Whether sourced from natural rubber trees or produced synthetically, rubber’s versatility and durability have made it indispensable in various industries. Understanding the intricacies of rubber production can deepen our appreciation for this ubiquitous material that plays a vital role in our daily lives.

Related articles also worth reading:

What’s the difference between Silicon and Silicone?

Silicone Rubber: A Versatile Elastomer in Industry

What is Synthetic Rubber?

Check out these other informative and educational articles:

Which rubbers are Fire Resistant / Fire Retardant?