When you need a highly reliable and long-term elastomer, Fluoroelastomer (FKM) could be your ideal solution.

Read on…

Let’s first explain how this…

becomes this…

It’s a combination of Living Chemistry, Production Engineering and Polymer Technology.

Fluorite Crystal (or Fluorspar) is a kind of mineral made of the compound Calcium Fluoride. This rock is pulverised into powder and the Fluorine is extracted by blending additional chemicals, and synthesizing together in huge refinery thermal crackers. These crackers operate at unimaginably high temperatures and pressures.

In the 16th century it was noted that Fluorspar would melt and flow when heated in a fire – so it was named Fluorine and comes from the Latin FLUERE meaning ‘to flow’.

So after thermal cracking the resultant gel material is the basis for Fluoroelastomer compounds – such as Viton™, Dyneon™, Aflas®, Dai-El®, Solvay® and Fluor-A-Com®. Accelerators, Carbon Black and Curatives are then mixed with the gum stock to create the desired compound for finished applications.

The Definition

Fluoroelastomers also known as fluorocarbon compounds are used in a wide variety of high performance applications. Long term reliability is the main reason fluoroelastomer is the go to polymer for all of those demanding and aggressive gasket sealing applications. These elastomers are specifically designed to be highly resistant to elevated temperatures (+200ºC continuous and +300ºC intermittent) and aggressive chemical changes. Fluoroelastomers have a great compression, sunlight and ozone resistance as well as a low gas absorption rate.

Fluoroelastomer gives exceptional performance – enabling you to reduce lifetime costs and cut out unscheduled downtime.

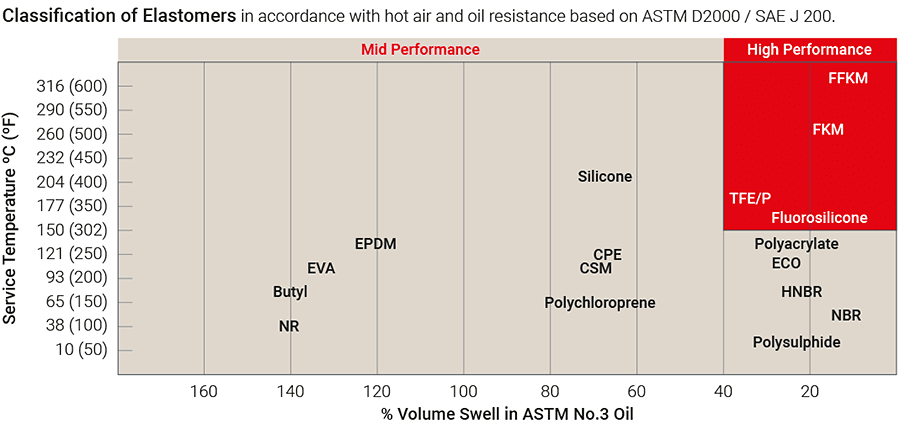

The ASTM D2000 designation for fluoroelastomers is HK, meaning one of the highest heat resistance and the lowest swell available of rubber type elastomers.

Chemical Resistance and Stability (what makes Fluoroelastomers work?)

There are three main factors that allow fluoroelastomers to gain their unique quality.

- Extremely strong bonds between atoms – the carbon atoms which make up the backbone of this polymer are extremely resistant to change. This means that these polymers are unlikely to undergo any division of their macromolecular chains into smaller sections, which would then be more susceptible to deterioration.

- High fluorine-to-hydrogen ratio – fluorine is the dominant atom, making it more stable and less likely to be affected by its environment. The higher the level of fluorine, the more stable the polymer.

- Single carbon backbone – the backbone contains only single bonds between the carbon atoms. Double bonds are increasingly more likely to be affected by chemical attacks; single bonds are less likely to be harmed by oxygen, ozone, UV lights, etc.

So what is the difference between FPM and FKM?

FPM is the international designation according to ISO, whereas FKM is the ASTM abbreviation. Both designations stand for the same base material: fluoro rubber.

Major Benefits of using Fluoroelastomer Products

FPM / FKM is a superior elastomer sealing material giving high performance in a wide variety of very demanding and critical current-day applications.

Exceptional performance

- Reduce lifetime cost of ownership.

- Stretch maintenance budgets for expensive plant & equipment.

- Cut unscheduled downtime.

- High temperature capability (long term in air up to 200°C).

- Resists aggressive oils & chemicals – Hydrocarbon fluids; amines; caustics; sulphur gasses; mineral oils & fats for example.

- Ensures compliance with tougher environmental regulations.

- Elimination of vapour emissions leading to reduction of greenhouse gasses.

- Low permeation of petroleum, oxygenate rich fuels & harsh engine oils.

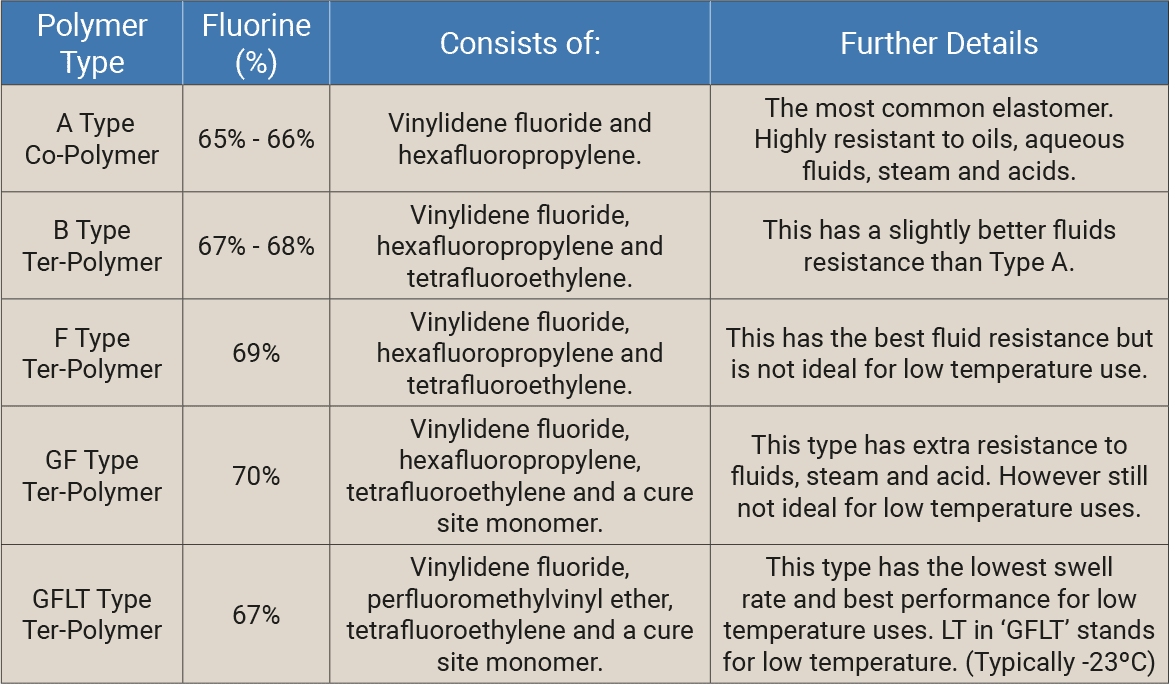

The Polymer Types

When choosing your Fluoroelastomer it is important to pick the right Polymer type for its intended use. We have identified the five main polymer types below. It is important to consider the Fluorine content percentage as this is what provides the greater resistance to swell and degradation.

click the table below to view larger

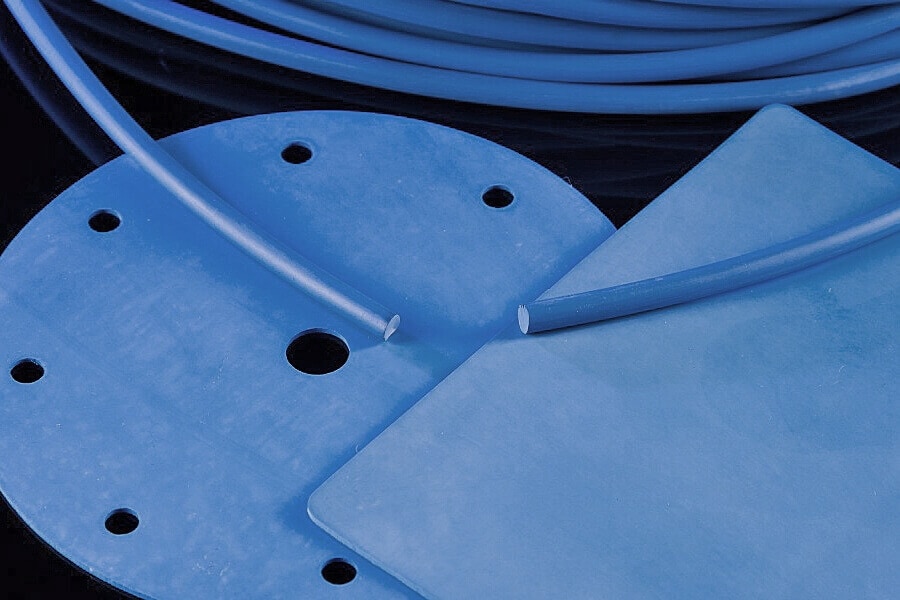

In addition J-Flex has developed an FDA Compliant FKM material suitable for food processing, beverage and pharmaceutical applications – available in either blue or off-white.

Applications and Industries

Fluoroelastomers can be used in a wide range of different industries, but they are especially beneficial to sectors that need highly reliable and long-term polymers.

The following industries are especially known for using fluoroelastomers:..

Main Markets

Global market volume is around 25,000 metric tons and growing at a minimum of 5% per year. The booming automotive market worldwide is propelling the growth and demand for fluoroelastomers.

- Industrial 11%

- Chemical & Petrochemical 12%

- Aerospace 17%

- Automotive 60%

Product Variations

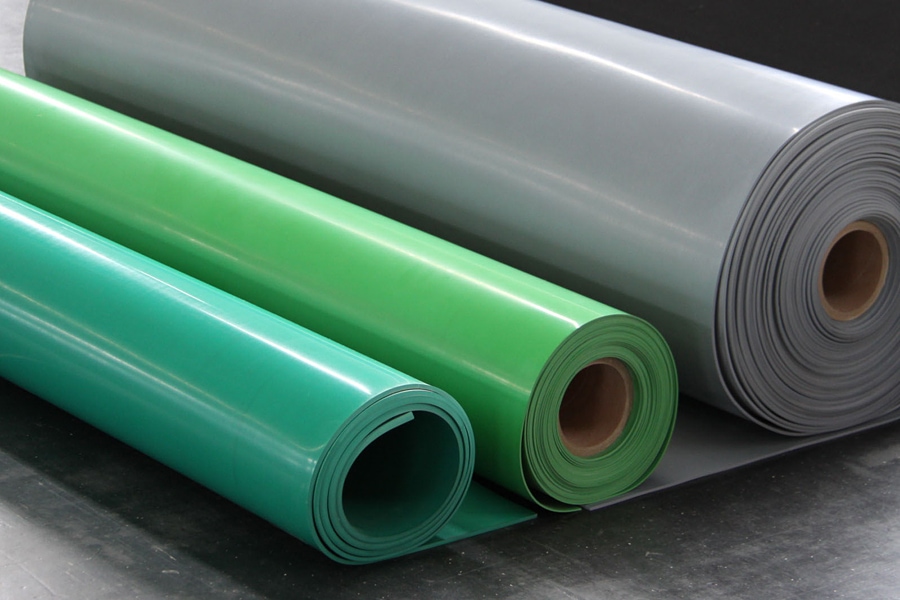

Fluoroelastomers can be found in a wide range of different shapes and sizes, depending on its intended use. At J-Flex, we provide one of the world’s largest stocks of fluoroelastomer sheet products and sponges. Adhesives, caulk sealants, custom mouldings, flue duct expansion joints,V-J rings, ‘O’ rings, gaskets and joints can all be made to order in a range of different colours, sizes and thickness.

Life Expectancy

Resistance to temperature extremes

Heat – FPM / FKM withstands high temperature and simultaneously retains its good mechanical properties better than most other elastomers. Oil and chemical resistance also are relatively unaffected by elevated temperatures. Compounds of FPM / FKM remain usefully elastic indefinitely when exposed to laboratory air oven ageing up to 204ºC or to intermittent test exposures up to 260ºC. High temperature service limits are generally considered to be:-

3,000 hrs at 232ºC

1,000 hrs at 260ºC

240 hrs at 288ºC

48 hrs at 316ºC

Who makes Fluoroeleastomers?

Fluoroelastomers are made and marketed by some of the world’s leading and largest chemical corporations. For example:

- Chemours – Viton™

- Dyneon Chemicals Dyneon®

- Solvay Solexis – Technoflon®

- Daikin – Dai-El®

- Chenqai – China

- 3F – China

- Dongyue – China

- Lanxess – Levatherm®

J-Flex is an official licensee of the Chemours Viton™ Scheme and we also offer other grades, and have one of the widest ranges of elastomers available worldwide. We understand you may have specific requirements and we will work with you to find the correct elastomer for your intended purpose.

A new fluoroelastomer family was introduced by Asahi Glass Co., FEPM based on an alternative copolymer of TFE and propylene. It is marketed under the trade name AFLAS®.