Here we answer some of the common questions regarding silicone sponge and silicone sponge sheeting.

What is silicone sponge sheeting used for?

Silicone sponge sheeting is used for a variety of purposes, including sealing, cushioning, vibration dampening, and thermal insulation. Some specific applications of silicone sponge sheeting include:

Gaskets and seals: Silicone sponge sheets are used to create airtight and watertight seals in various industries, such as automotive, aerospace, and electronics. They provide excellent resistance to weathering, UV radiation, and extreme temperatures. See our Custom Cut Gaskets & Seals page.

Cushioning and shock absorption: Silicone sponge sheets are used as padding or cushioning material in packaging, electronics, and medical devices. They can absorb shocks and vibrations, protecting delicate components or products during transport or use.

Thermal insulation: Due to their low thermal conductivity, silicone sponge sheets are used to insulate and protect components that are exposed to high temperatures, such as in industrial ovens, furnace seals, or engine gaskets.

Sound dampening: Silicone sponge sheets can be used as soundproofing material in various applications, including architectural settings, automotive industry, or HVAC systems. They can reduce noise transmission and improve acoustic isolation.

Electrical insulation: Silicone sponge sheets are used as electrical insulators due to their excellent dielectric properties. They can be used to cover electrical wires or components, providing protection against electrical shocks or short-circuits.

Overall, silicone sponge sheeting is a versatile material with numerous applications where properties like flexibility, high-temperature resistance, and sealing capabilities are required.

What industries is silicone sponge sheetings used in?

Silicone sponge sheetings are used in various industries including:

Aerospace: Silicone sponge sheetings are used in the aerospace industry for applications such as gasketing, sealing, and thermal insulation.

Automotive: They are utilised in the automotive industry for gasketing, cushioning, sealing, and vibration dampening purposes.

Electronics: Silicone sponge sheetings are commonly used in electronic devices for cushioning, shock absorption, and insulation. They can protect delicate electronic components from damage and provide thermal management.

Medical: In the medical industry, silicone sponge sheetings find applications in healthcare equipment, medical devices, and prosthetics due to their biocompatibility, sterilisation resistance, and flexibility.

Industrial Manufacturing: These sheetings are employed in industrial applications such as sealing, insulation, and noise reduction in equipment, machinery, and production processes.

Food and Drink: Silicone sponge sheetings are used in the food processing industry for applications like gaskets, seals, and vibration dampening, as they are non-toxic, FDA-compliant, and resistant to extreme temperatures.

Construction: Silicone sponge sheetings are utilised in the construction industry for sealing joints, providing thermal insulation, and reducing vibration and noise in various structures or building components.

Renewable Energy: They find applications in renewable energy systems like solar panels and wind turbines for gaskets, sealing, and thermal management purposes.

Marine: Silicone sponge sheetings are used in the marine industry for sealing and gasketing applications, as they have excellent resistance to saltwater, UV rays, and extreme temperatures.

Consumer Products: They are utilised in various consumer products such as home appliances, sporting goods, footwear, and personal care items, where cushioning, insulation, or sealing properties are required.

What’s the difference between silicone foam and silicone sponge?

Silicone foam and silicone sponge are both versatile materials used in various industries, They are two different materials with distinct properties. Here’s how they differ:

Composition: Silicone foam is typically composed of silicone rubber and a blowing agent, which creates gas bubbles or cells in the material. This results in a more open-cell structure, similar to regular foam materials like polyurethane foam and has interconnected air pockets that allow for airflow and compression. On the other hand, silicone sponge is made by incorporating a filler material into the silicone rubber, creating a closed-cell structure, meaning its cells are sealed off from each other.

Density & Compression: Silicone foam generally has a lower density and is softer compared to silicone sponge. It is more compressible and offers better cushioning and shock absorption properties and will quickly recover its shape when pressure is released. Silicone sponge, being denser and more rigid, provides higher compression strength and is better suited for applications requiring stability and resistance to deformation.

Thermal Insulation: Due to their differing structures, silicone foam and silicone sponge have different thermal insulation properties. Silicone foam, with its open-cell structure, allows air circulation within the material, making it a better thermal insulator. Silicone sponge, with its closed-cell structure, offers less thermal insulation but provides superior resistance to heat transfer – it has a higher compressive strength and slower recovery rate.

Water Absorption: Silicone foam has higher water absorption capabilities due to its open-cell structure, which can be advantageous in certain applications, such as sealing against moisture or creating water-resistant barriers. Silicone sponge, with its closed-cell structure, has lower water absorption properties.

Applications: Both silicone foam and silicone sponge find applications in various fields. Silicone foam is commonly used in cushioning, padding, and vibration dampening applications. Silicone sponge is often utilised for sealing, gap filling, insulation, gaskets, thermal management applications and other applications requiring a reliable barrier against external elements. It provides a reliable seal against dust, air, water, and other environmental elements. Silicone foam, with its open-cell structure, is not ideal for sealing purposes as it allows for permeability.

It’s important to note that specific properties, densities, and compositions of silicone foam and silicone sponge can vary from product to product, so it’s always best to consult the manufacturer or supplier for detailed specifications and guidance. Overall, while both silicone foam and silicone sponge are made of silicone polymers, their different structures and properties make them more suitable for specific applications.

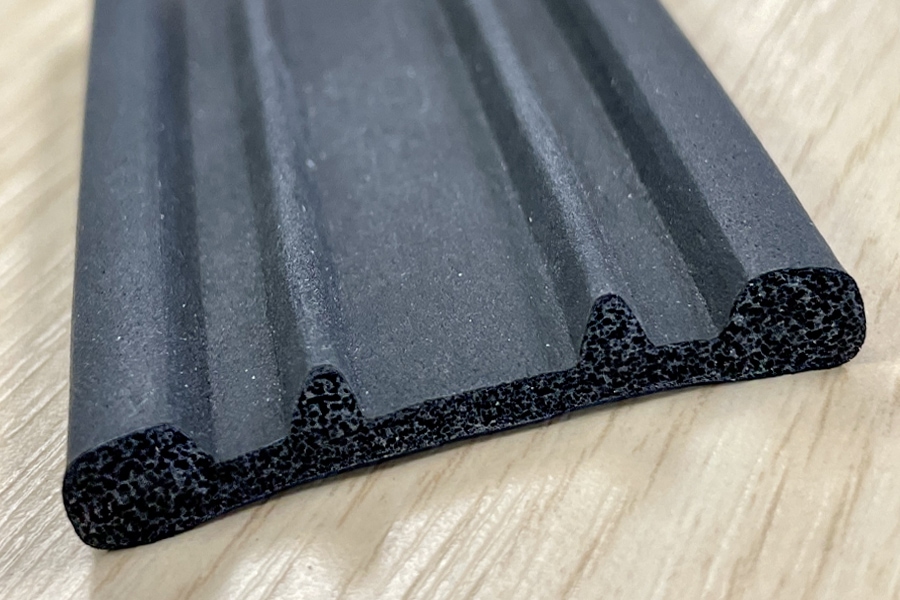

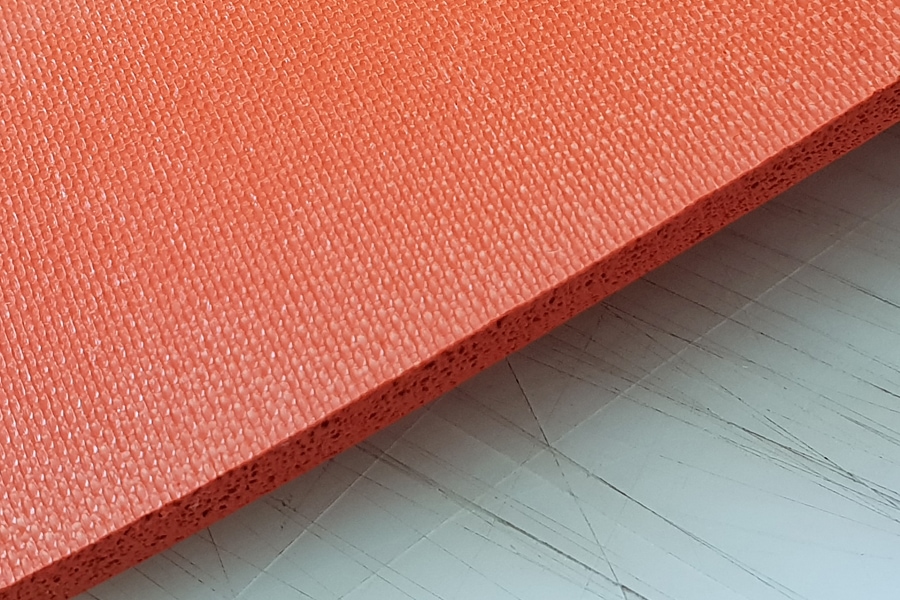

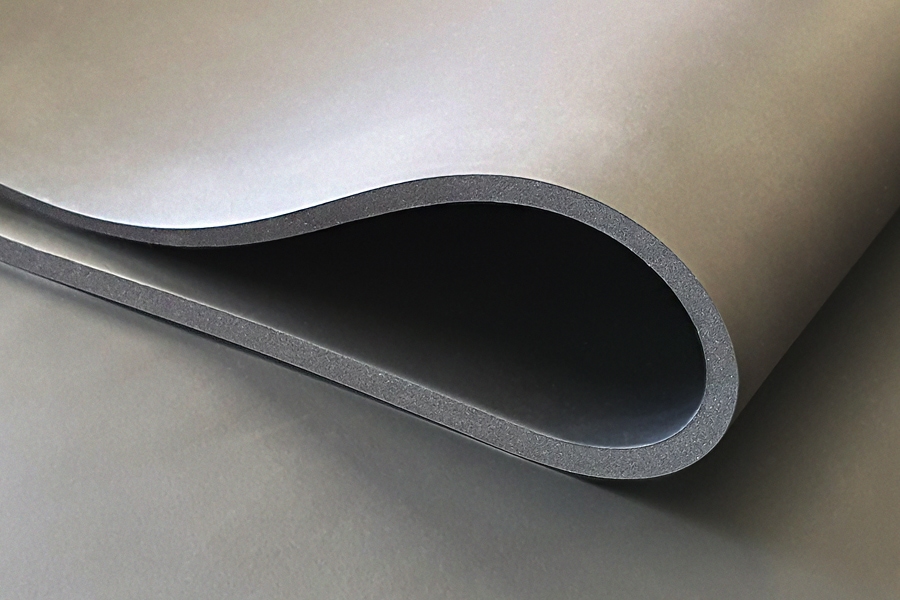

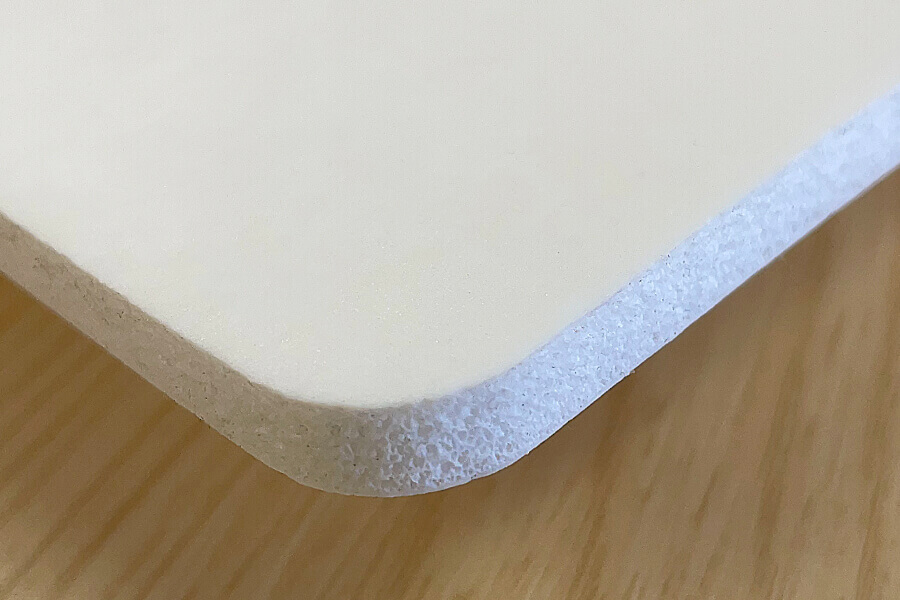

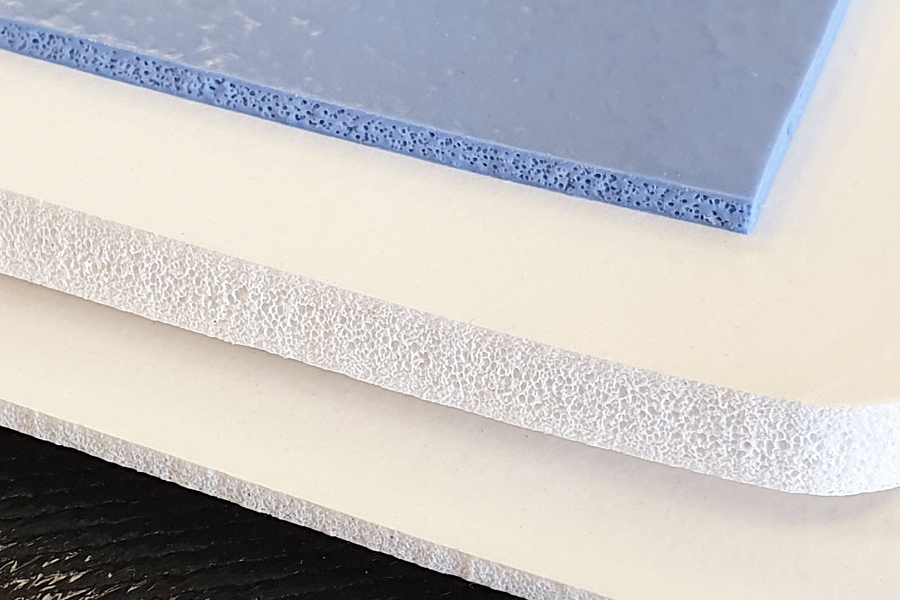

A few examples of various silicone sponge types.