It’s good to finally see various forms of motorsport now getting back into gear, alongside the many automotive manufacturers now resuming production.

What does this mean to us here at J-Flex?

Find out how we play our part – or should that be parts?

Membranes

Specifically vacuum forming membranes. These are specially designed rubber membranes ideal for veneer foil pressing & composite lamination, including GRP & Carbon Fibre reinforced polymers, used within the Automotive industry, and also Furniture, Marine & Aerospace markets. Our trademarked Vac-Sil® Supreme product offers truly impressive elasticity and excellent drawdown on awkward shapes – it’s suppleness being very sympathetic to sharp undercuts and irregular shapes. (see the video below).

Whilst we can’t say who specifically, we can comfortably say it has been well received by a number of well known manufacturers of prestige vehicles and high performance supercars, as well as Formula One (F1). Typical uses are for the forming of composite chassis components and that of interior trim panels with various laminates.

Moulded Components

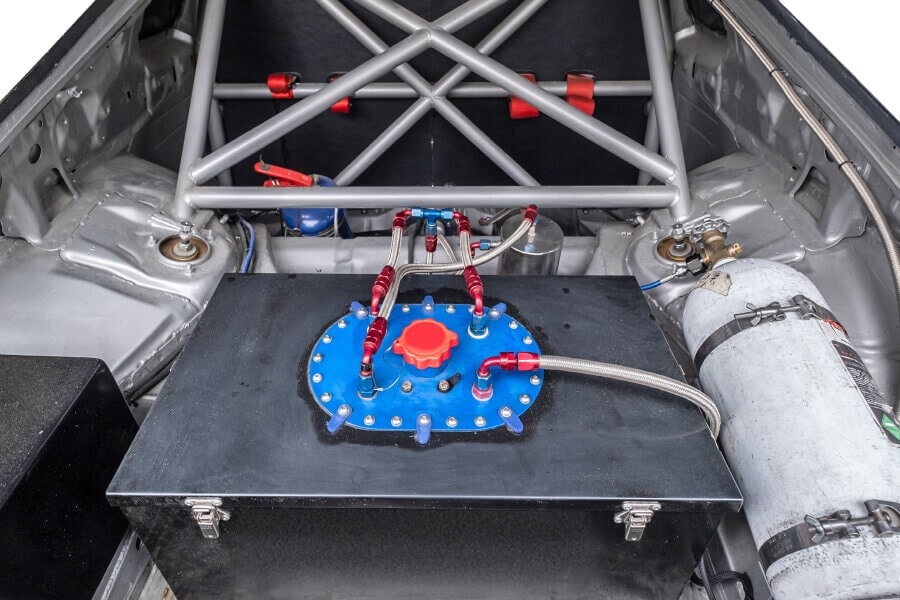

This could literally be any moulded shape for any purpose. Maybe a new component that has never been produced before, an improved replacement version, or sometimes the reproduction of now obsolete OEM parts, typically for classic and unique vehicles.

Some examples include:

- Bellows/boots to protect moving parts and joints

- Motorcycle fuel tank pads

- Provision of vibration protection to components made from other materials

- Moulded Seals

Seals, Gaskets & O-rings

Put simply, all those numerous items that stop liquids such as water, oils, fuels getting into, or out of, something or somewhere!

Also used for:

- items regarding vibration protection for critical systems

- areas such as audio, lighting & air conditioning.

Sheetings

There are a number of rubber sheeting types depending on the application and special requirements. Different thicknesses, hardnesses, and other properties (fire resistance, oil & fuel resistance, etc.) all help provide solutions to a variety of automotive applications – using both silicone sheeting and silicone sponge sheeting.

Some examples include:

- Diaphragms on fuel pump systems

- Fuel bladders for high-performance race cars (and marine vessels)

- Seals and gaskets as described above

- Audio, lighting & air conditioning parts

Need to know more? – just ask the experts here at J-Flex – call us on +44 (0)1777 712 400 or fill in our Ask the Experts form