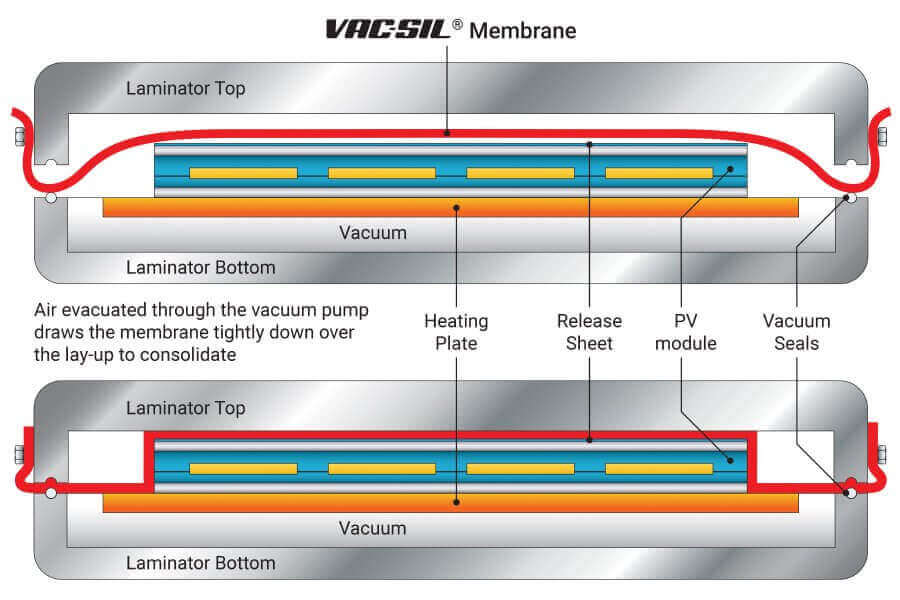

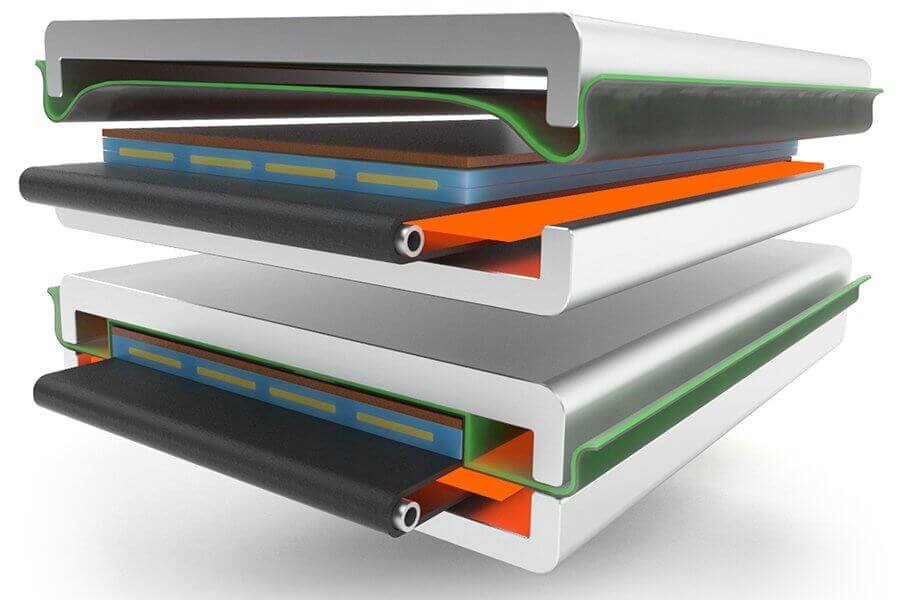

Our proven VAC-SIL® quality silicone rubber Membranes have been specifically designed for use as vacuum forming membranes for Solar/P.V. module lamination and the forming or thermo-pressing of vinyl foil veneers on furniture woodwork, as well as for composites in the Aerospace, Automotive (including F1 and EV), Marine industries, and on other general products.

Listening to our valued customers and their experiences, VAC-SIL® Quality Membranes have been polymer engineered to give users excellent thermal and mechanical properties, with good chemical resistance that leads to optimum service life.

We can also supply a range of components for solar panel production, such as: Squeegee Edge Profiles, Beltings, Vacuum Seals and Release Sheets. Visit our Precision Components page.

Need help deciding which grade of Vac-Sil® best suits your needs?

Download our handy Comparison Spec Sheet

Scroll down for informational downloads.

Precision cutting

We have a large precision cutting facility, capable of cutting Membranes, and other rubber/elastomer sheeting, up to 3.2m wide, ensuring total accuracy for product sizing, cut-out portions, holes & slots.

Advantages

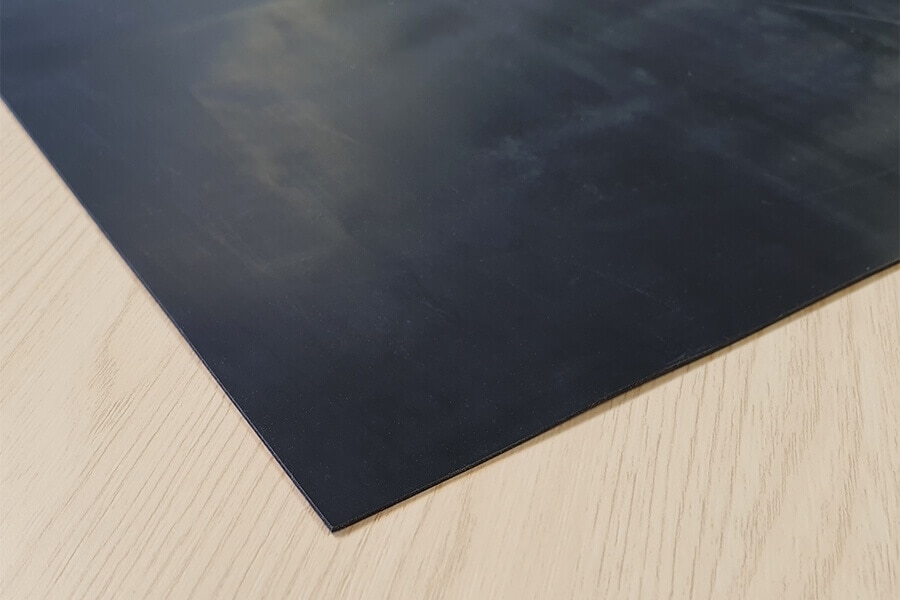

- Excellent Life Cycle Performance

- 1mm thickness

- 35º Shore

- High Tensile Strength 8.5 MPa

- High Temperature +200°C

See our video of Supreme in use – we think you’ll be as impressed as our current high profile clients are.

Advantages

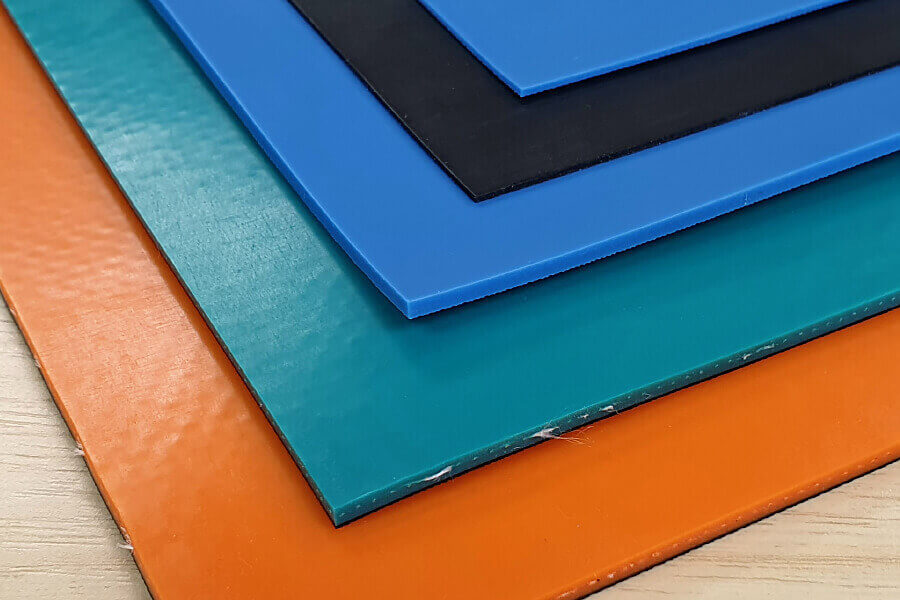

- Unique Blue colour

- Good Life Cycle Performance

- 1.5 and 3mm thicknesses

- Most economic grade

- 55º Shore

- High Tensile Strength 7.0MPa

- High Temperature +200°C

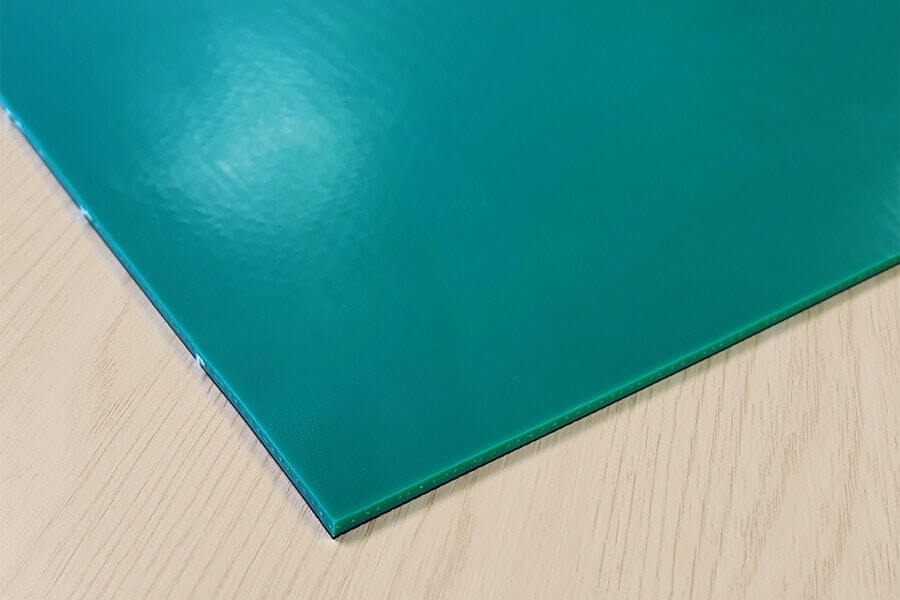

Advantages

- Unique Green/Black composite

- Very Good Life Cycle Performance

- Black gas side – Peroxide / E.V.A. Resistant Barrier

- 1 layer fabric reinforcement – tough mechanical strength

- 3.8mm thick

- Most cost-effective grade

- 55º Shore

- Maximum UPTIME

- Temperature +150°C

Advantages

- Unique Orange/Black composite

- Highest Life Cycle Performance

- Black gas side – Peroxide / E.V.A. Resistant Barrier

- 1 layer fabric reinforcement – tough mechanical strength

- 4mm thick

- Guaranteed for long life

- 55º Shore

- High Temperature +200°C

Areas of use for Vac-Sil®

Solar Energy

The Vac-Sil® range of smart membranes from J-Flex are used extensively in the production of Solar PV panels, offering outstanding performance.

Automotive

Used in the placing of finishes to car interior parts such as doors, dashboards and centre consoles – typically for luxury vehicles and supercars as well as the production of chassis tubs and other parts using composites. More info here.

Furniture

Used for the process of applying decorative foil veneer finishes to kitchen doors and carcasses.

Marine

Used for the process of applying decorative foil veneer finishes to various items in yachts and ships, such as tables, instrument panels, cupboards and decorative trim.

VAC-SIL® is a registered trade mark of J-Flex

VAC-SIL® Membranes bring many positive advantages – including:

- Laboratory controlled membrane production

- Material totally post-cured = maximum mechanical properties

- Membranes up to 3850mm wide

- Membranes precision cut using CAD and digital cutting equipment

- Holes, slots & curves – no problem!

- Huge stocks of base materials

- Ex-stock or delivery by agreement

- Unique VAC-SIL® 9-Point Quality Plan

- Premium product packaging

- Excellent cycle life – up to 10,000 cycles

- Temperature resistant

- Great strength & tear resilience

- Excellent release properties

- Laboratory controlled membrane production

- Material totally post-cured = maximum mechanical properties

- Membranes up to 3850mm wide

- Membranes precision cut using CAD and digital cutting equipment

- Holes, slots & curves – no problem!

- Huge stocks of base materials

- Ex-stock or delivery by agreement

- Unique VAC-SIL® 9-Point Quality Plan

- Premium product packaging

- Excellent cycle life – up to 10,000 cycles guaranteed*

- Temperature resistant

- Great strength & tear resilience

- Excellent release properties

Membrane Cycle life can be variable as there are many factors outside of our control that make it very difficult to give a cast iron guarantee. However, we have been in the Solar business for a long time now – over 10 years now – so taking account of these variables we give a warranty guide as detailed in the descriptions for each grade. See our White Paper: “A Guide for Optimising Membrane Performance”.

Download our handy Comparison Spec Sheet