So, what makes Nitrile Rubber (NBR) unique?

Nitrile rubber, also known as NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene.

Although its physical and chemical properties vary depending on the polymer’s composition of nitrile, this particular type of synthetic rubber is unusual in being generally resistant to oil, fuel, and other chemicals. So, the more nitrile within the polymer, the higher the resistance to oils but the lower the flexibility of the material.

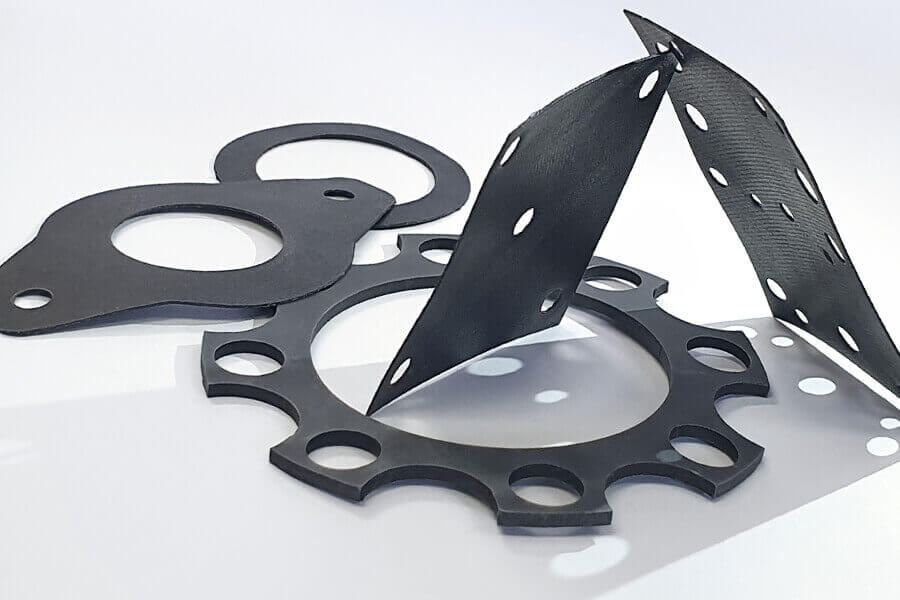

Nitrile is the most widely used elastomer in the seal industry today. It is used in the automotive and aeronautical industry to make fuel and oil handling hoses, seals, grommets, and self-sealing fuel tanks, since ordinary rubbers cannot be used. NBR’s ability to withstand a range of temperatures from -40 to 108 °C (-40 to 226 °F) makes it an ideal material for aeronautical applications. Nitrile butadiene is also used to create moulded goods, footwear, adhesives, sealants, sponges, expanded foams, and floor mats. The uses of nitrile rubber include disposable non-latex gloves, automotive transmission belts, hoses, O-rings, gaskets, oil seals, V belts, static & dynamic hydraulic seals, synthetic leather, printer’s form rollers, and as cable jacketing; NBR latex can also be used in the preparation of adhesives and as a pigment binder.

Typical applications: Aircraft Fuel Systems, Automotive Fuel Systems, Off-Road Equipment & Marine Fuel Systems.

Its resilience also makes NBR a useful material for disposable lab, cleaning, and examination gloves. Nitrile rubber is more resistant than natural rubber to oils and acids, with superior strength, but does have less flexibility. Nitrile gloves are therefore more puncture-resistant than natural rubber gloves, especially if the latter are degraded by exposure to chemicals or ozone. Nitrile rubber is also less likely to cause an allergic reaction than natural rubber. Unlike polymers meant for ingestion, where small inconsistencies in chemical composition/structure can have a pronounced effect on the body, the general properties of NBR are not altered by minor structural/compositional differences.

Nitrile’s can be specially compounded to meet International Food Standards such as FDA 21.177 2600; (EC) 1935:2004; BfR XXI.

Properties of Nitrile (NBR) Rubber

Typical compounds have good resistance to mineral oils, vegetable oils, benzene/petrol, ordinary diluted acids and alkalines.

An important factor in the properties of NBR is the ratio of acrylonitrile groups to butadiene groups in the polymer backbone, referred to as the ACN content. The lower the ACN content, the lower the glass transition temperature; however, the higher the ACN content, the better resistance the polymer will have to nonpolar solvents. Most applications requiring both solvent resistance and low temperature flexibility require an ACN content of 33%.

| Property | Typical Value |

| Hardness, Shore A | 30 - 90 |

| Tensile failure stress, ultimate | 500 - 2500 PSI |

| Elongation after fracture in % | 600% maximum |

| Density | Can be compounded around 1.00 g/cm3 |

A warning notice:

Beware of “Commercial” Quality Nitriles. These are normally clever chemical concoctions of SBR & Nitrile. This is done to cheapen the product, but this clever bit of chemistry has only one certain result – the 2 polymers are compromised for an exacting application where you would expect a “normal” Nitrile to do the job. These Commercial Qualities normally have no more than 10% ACN content – so BEWARE!

Storage of Nitrile/NBR Rubbers

NBR parts should be kept away from direct sun-light. For more detailed information on storage refer to ISO 2230:2002 – Rubber Products – Guidelines For Storage.

In line with this standard if stored correctly, Nitrile/NBR materials are defined as a Group B Rubber and as such have an initial shelf life of 7 years, with a 3 year extension period. Again, if you have been sold a Commercial Quality with SBR as a blend material this may alter the shelf life & extension period.

I’ve heard of a Nitrile called HNBR, what is it?

Good question. Hydrogenated nitrile butadiene rubber (HNBR) – also known as highly saturated nitrile (HSN) – is known for its physical strength and retention of its properties after long-term exposure to heat, oil and chemicals. A common use is O-rings for automotive air-conditioning systems.

Depending on filler selection and loading, HNBR compounds typically have tensile strengths of 20-31 MPa when measured at 23°C. Compounding techniques allow for HNBR to be used over a broad temperature range, -40 °C to 165 °C, with minimal degradation over long periods of time. For low-temperature performance, low ACN grades are advised; high-temperature performance can be obtained by using highly saturated HNBR grades with white fillers. As a group, HNBR elastomers have excellent resistance to common automotive fluids (e.g., engine oil, coolant, fuel, etc.) and many industrial chemicals. Like NBR, fluid and chemical resistance improves as the ACN content is increased.

The unique properties and higher temperature rating attributed to HNBR when compared to NBR has resulted in wide adoption of HNBR in automotive, industrial, and assorted, performance-demanding applications. The automotive market is by far the largest consumer, using HNBR for a wide range of dynamic and static seals, hoses, and belts. HNBR has also been widely utilised in industrial sealing for oil field exploration and processing, as well as rollers for steel and paper mills.

What about Carboxylated nitrile butadiene rubber (XNBR)?

Carboxylated nitrile butadiene rubber (XNBR) is basically an improved version of nitrile butadiene rubber (NBR). Typical uses are oil resistant applications in automotive, marine and aircraft fuel systems, where high strength and abrasion resistance is required. It has good resistance to oils and non-polar solvents and has an improved tear strength and abrasion resistance when compared to NBR. Conversely it does have poor ozone and weathering resistance, as well as poor steam resistance.

NBR is also blended with PVC for special applications such as Floating Roof Tank Seals & Profiles, where good resistant to aromatic fuels is required.

In Summary

Standard Nitrile/NBR Rubber will cover the majority of cases, with the more costly variants of HNBR and XNBR being employed in more specialised instances.

You can also download our nifty Nitrile Comparison Chart, with lots of useful information.

Need to know more? – just ask the experts here at J-Flex – call us on +44 (0)1777 712 400 or fill in our Ask the Experts form

You may also be interested in our White Papers – available to download here.